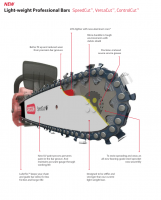

This is what the inside of your nose looks like (

er, at least the inside of your guide bar sprocket nose!).

Depending on the type, size, brand, etc. of bar, there might be 15 to 40 little roller bearings in there. Conventional wisdom is to

always grease the tip,

or to

never grease the tip, but not to go part way.

The

always greasers keep flushing grease into the bearings, which keeps them lubricated, and pushes out the gunk. The

never greasers allow bar and chain oil to drizzle down into the bearings, keeping them lubricated.

Sometimes greasing causes a problem , since the old grease can mix with saw dust, creating a dam that keeps the bar and chain oil out, resulting in dry bearings.

Most Oregon and Husqvarna bars (photo above) traditionally come with a greasing hole. Most STIHL bars do not. However, STIHL bars are built with thin shims on either side of the bearing/sprocket assembly to help keep debris out. The newest Oregon Speedcut bars do not have the holes, and are described as 'lubricated for life'.

http://www.oregonproducts.com/speedcut/

I do not grease my personal nose sprockets. If I get a used guide bar with a grease hole, I clean it out with solvent to prevent any dams, then spray it out with WD-40 to prevent rusting until I use it with bar and chain oil. I like to keep my nose clean!

I'd like to try to seal the grease holes but haven't thought of a good way to do this without a tac weld which may do harm

No need. Not much will get in through those small holes that will not get in between the sprocket and the inside wall of the bar.

Philbert