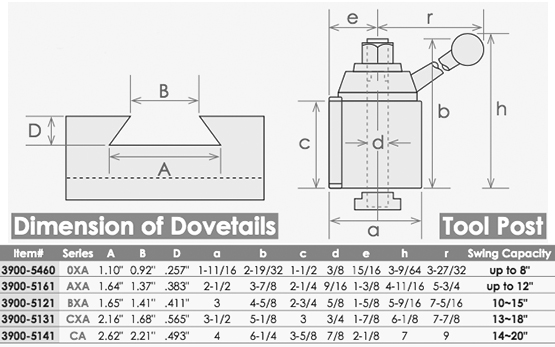

The Dorian and Aloris use letters for the sizing where the rest of the world uses numbers. So AXA = 100 series, BXA = 200, CXA = 300 and so on. The tool post and tool holders should be marked. If not you can use the charts below to figure it out.

There is a 0XA (000) size but that is for really small lathes, less than 8" swing.

With the 12" lathe you are in the transition from AXA all the way to CXA. The real deciding factor is the vertical distance from the lathe centerline to the top of the compound. If the height of the bottom lip of the tool holder plus the tool height is larger than this distance then you can't get your tool down to the centerline. See the CH Min/Max from this chart.

View attachment 348595

This bigger the Quick Change Tool Post (QCTP) the larger the tooling you'll be able to use. There are #1 and #2 XL tool holders that allow you to use a little larger than standard tooling, in a BXA the normal tooling is 1/2", the XL allows for 3/4" but needs an extra 1/16" drop down on the toolpost.

View attachment 348594

If you are looking to buy a QCTP I'd go with a wedge style vs. a piston. They are a little more expensive but the tool offset is way more consistent and it is a little more rigid.