- Local time

- 4:41 AM

- User ID

- 10894

- Joined

- Nov 6, 2019

- Messages

- 305

- Reaction score

- 948

- Location

- Salem, Missouri

I'm sorry if this has been covered before but this is the only place I really trust to get this info.

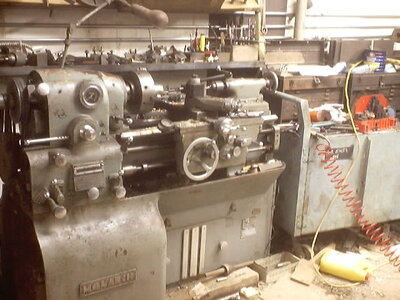

So I'm in the market for a lathe or end mill. I've never operated either and want to start cutting cylinders and other small parts.

My questions are....

for doing cylinders am I going to be better off with a lathe or mill?? I'm assuming a lathe is the way to go.

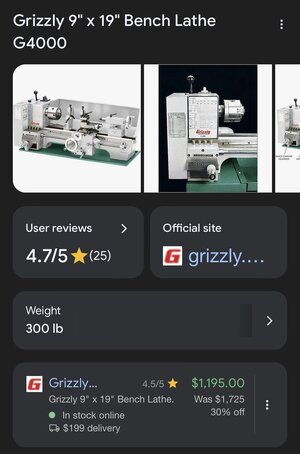

Next what's the smallest swing I should be looking for to do squish bands and bases?? I'm assuming a 9" swing with a 19" bed is probably about the minimum I'd want to go with a 4 jaw chuck.

Last question is what are some brands I should stay away from entirely when looking at new lathes and tooling??

Thank you in advance for any info you can share on this.

So I'm in the market for a lathe or end mill. I've never operated either and want to start cutting cylinders and other small parts.

My questions are....

for doing cylinders am I going to be better off with a lathe or mill?? I'm assuming a lathe is the way to go.

Next what's the smallest swing I should be looking for to do squish bands and bases?? I'm assuming a 9" swing with a 19" bed is probably about the minimum I'd want to go with a 4 jaw chuck.

Last question is what are some brands I should stay away from entirely when looking at new lathes and tooling??

Thank you in advance for any info you can share on this.