OnlyStihl

Super OPE Member

I think by scrap pile he means his steel pile at home for building stuff

Bill G, knows this. He's just trying to stir up some shiet.

I think by scrap pile he means his steel pile at home for building stuff

Once again the old adage .One mans poison is another mans meat.The conversation over a piece of plate steel is not like a gold ingot .As far as "scrap " steel I have it by tonnage and I never paid for a pound of it .Some might be repurposed and some could lay in a pile the next 200 years until it rusts way to nothing .My shop.60 by 70 is with the exception of the roofing matterial is all recyled so called scrap .

If you were here tomorrow morning you would see what goes to the mill. It will be a real eye opener for some.I did buy new steel once. Crazy expensive. I need about 40 to 50 feet of square tubing to modify my trailer with higher railings. There's got to be some around, just waiting on someone that needs some cash, or an estate sale, etc.

It's actually funny that Bill G thinks I go to garage sales, buy metal and then take it to a scrap yard for recycling. Again, he's just trying to bait someone into a pissy fight over word definition or use.

It is so strange that Ebay doesn’t extend bidding time after each bid like most auction sites do. OTOH, I have scored some fantastic deals as a sniper with screeching fast fiber optic.Bill is great sport going back years .I have an extremely fast internet connection and used to snipe outbid him on flea bay with 2 seconds left on the time .

How would this battleship anchor fare in the US?

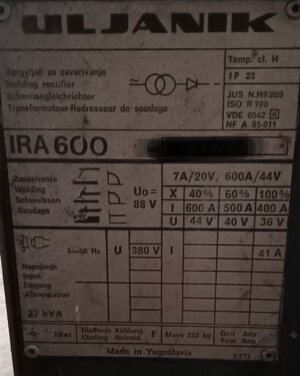

252kg of transformer power, continuous 400Amp, 60% 500Amp, 40% 600Amp.

View attachment 479629

No idea whether it still works as I need to figure out electricity supply, but it is mine.

I was told it is functional though.

I guess I can always utilize it as a doorstop considering that I own no Stihl products!

I found some sticks that go with that welder.

That is a male/mans hand holding them.

View attachment 479731