Wolverine

dilligaf

- Local time

- 3:07 PM

- User ID

- 373

- Joined

- Jan 1, 2016

- Messages

- 7,118

- Reaction score

- 35,933

- Location

- 17325

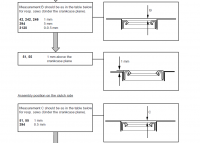

Daggum! That seal is,, gone! Props to the operator for not roaching a p/c with that much of a leak?So I popped the flywheel and found the seal in two pieces. Not the rubber, but the steel outer housing of the seal. Would this be due to incorrect assembly?? Like maybe the seal was not seated deep enough and the flywheel hub was rubbing on it?? This was my first rebuild that went this deep and I'm fully prepared to accept a mistake on my part.

The more I look at this the more I think the seal wasn't seated quite deep enough and the flywheel was rubbing it.

And I will be putting new bearings in along with the seals. It's not my saw and I want to make sure it's good. I still don't like the looks of that PTO side bearing. Looks like it got pretty hot

View attachment 153333

Dug up an old pic of when I did seals in mine and zoomed in. I'm going to guess yours wasn't in far enough (I'm no authority btw).

EDIT: After looking more, I can't really tell where the outter rim of your seal is, so maybe I'm wrong.