- Local time

- 6:24 AM

- User ID

- 15730

- Joined

- Feb 14, 2021

- Messages

- 436

- Reaction score

- 2,752

- Location

- Wisconsin

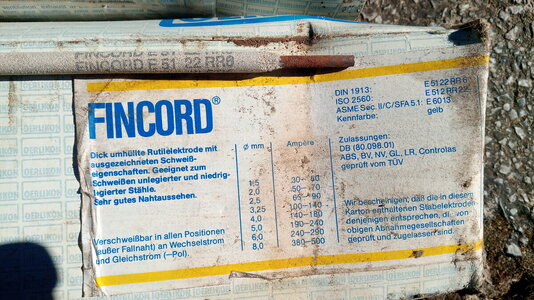

Funny story; We have a few guys in our shop who will happily seek out the best looking tooling for a job they are working on, and then proceed to destroy it. When they are done, they will put chipped and dull endmills and taps back where they found them, and not order replacements or mark the tools to get re-sharpened

I had to order a 1" endmill 2 years ago, for a bearing housing we were machining out of Cast Iron. I didn't spend a ton of money on it, as you can see by the color of it's sleeve. As a joke, I wrote "Garbage" on the outside of it, hoping to deter the tool thieves from using a brand new endmill to chew weld off of something, leaving me with nothing to finish what I was doing.

Two years and counting, and the same tool is still usable and hidden in plain sight. Sharpie markers are powerful tools haha