Ozarker

Well-Known OPE Member

- Local time

- 7:21 PM

- User ID

- 589

- Joined

- Jan 18, 2016

- Messages

- 62

- Reaction score

- 137

- Location

- Boston Mountains, Ozark Plateau

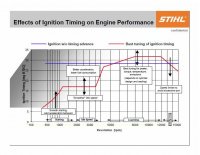

There's a lot written about limited coils, but does anyone know how they're made to be limited, and how it is that they come into play at certain rpms? Is this all a matter of electronic circuitry, or is there some other method employed?

Does anyone know at what rpm they kick in? I would expect that this would vary somewhat between models, and manufacturers but perhaps not?

Does anyone know at what rpm they kick in? I would expect that this would vary somewhat between models, and manufacturers but perhaps not?