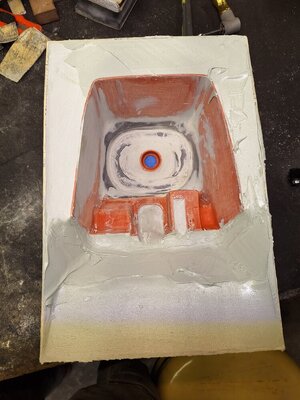

I found out in this chapter my dyslexia is dyslexic. My wife said to me, "You're trying to turn your brain inside out!". I was indeed. And back, and forth, and so on. The challenge in my mind was a dimensional one. Dimensia? Idk. The plastic these things are made of is roughly 0.060" thick. I ordered petg sheet at the same thickness. The end goal is to be able to vacuum form covers, as to not pucker everytime someone else's dogs dig into this thing in the saw box on the bucket truck. I wanted to have a care free attitude about the plastics on this saw so it could do work and prove whether or not the guts would hold up....

So. How do I make a mold, then a buck, that carries the exact inside dimensions, so that I can pull a form over the outside, and it looks like it fits... We'll, I'd have to cast the inside then.