Demsawzdo37

Well-Known OPE Member

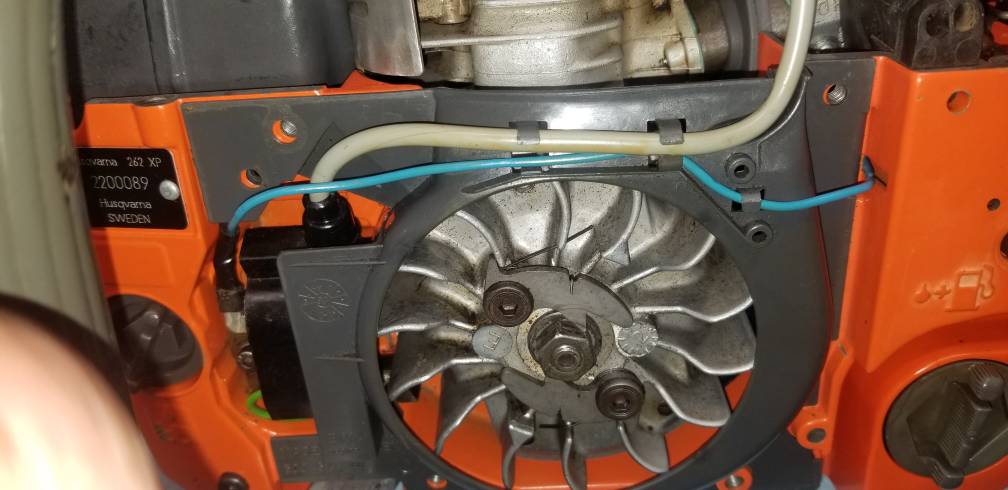

I used a center punch and made a couple alignment dots and slightly advanced the timing. So yes I feel at this point the flywheel is set correctly. If it does spark it's very weak almost none exsisting.Is the flywheel on in the correct position? Did I miss that?

The cast in keys for flywheels drive me crazy. I've had a few saws where I notch out the flywheel where the key was and then form a piece of Romex copper to make a key. It's not exact but it does work quite well. The key really is just for positioning ....the taper is what really holds the flywheel.

I like the idea of ruling out the switch too.

My dads 257 has done well with an aftermarket coil....though I've become less of a fan of them.

Sent from my SM-N950U using Tapatalk