Philbert

Chainsaw Enthusiast

- Local time

- 11:13 AM

- User ID

- 737

- Joined

- Jan 30, 2016

- Messages

- 4,441

- Reaction score

- 17,939

- Location

- East Dakota

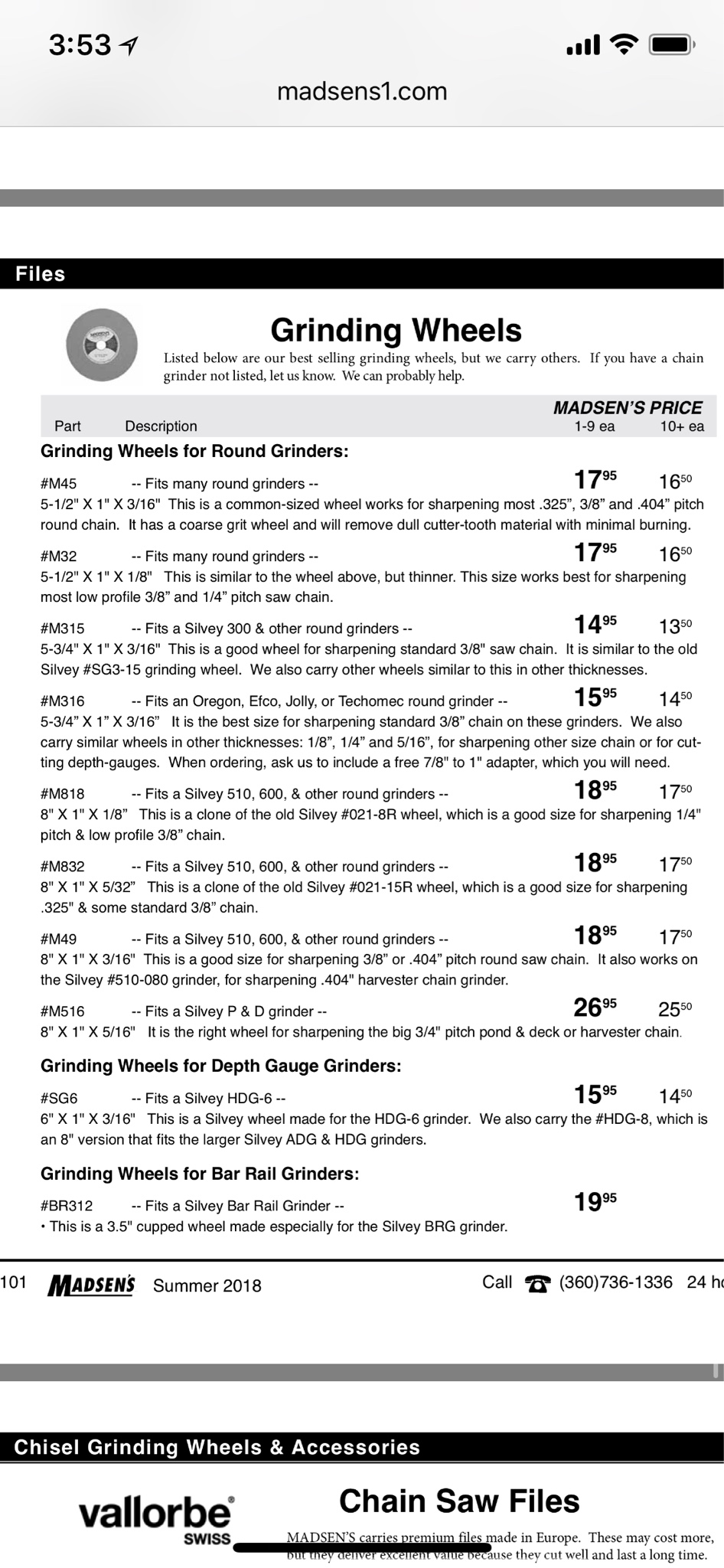

How do I get someone's worn down wheels with an inch hole to go on my old little hole grinder? Someone have a line on arbor bushings?

A member with a lathe made a 1" (Silvey) to 7/8" (Oregon) diameter arbor bushing adaptor for me. It fit some wheels and some grinders (I have a few). Not all. Thousandths matter.

If these we're commercially available, even if by a member, that would be great. I would definitely be interested!

Philbert