J & L Creations

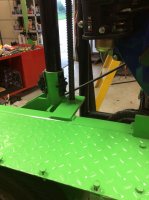

Machine Design

That leads to thought number two RV camper frame. High speed axles and brakes and you just about can't give an old one away(honest).

I was also considering an old school bus frame or truck frame that would be really straight.