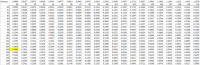

Special thanks to Shaun for that measurement. Here is a chart specific to this saw that shows the bore distance across various timing changes.

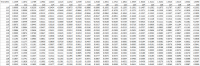

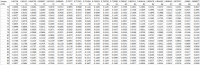

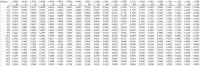

It works as follows:

1. Find your current port timing number.

2. Follow the row across until you find the timing number you want.

3. The corresponding value is the distance between the two in ten thousands of an inch.

4. A positive value means you would need to grind material. Negative would require decking or epoxy.

Example: Suppose I dropped the exhaust to 105 and I want to go to 90 to do sick piss revs. Go to the 105 row, then look at the 90 column. I would have to grind up .1961" (highlighted yellow).

You can also use the tables to predict where timing will end up when decking. Suppose my transfers are at 115 and I knock .050 off the base. Go to 115 and scan across the row for .050. 120 is at .0528 so I'll end up around 119.5.

Let me know if it works for you guys

Exhaust

View attachment 122894

Transfers

View attachment 122892

Intake

View attachment 122893