bikemike

Pinnacle OPE Member

- Local time

- 9:49 PM

- User ID

- 768

- Joined

- Feb 4, 2016

- Messages

- 2,263

- Reaction score

- 5,437

- Location

- Cottage grove mn

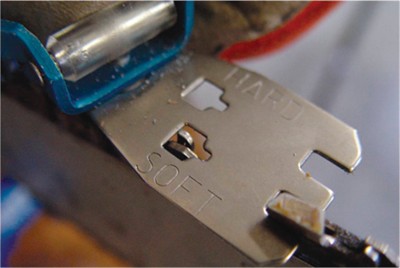

I angle mine with a grinder or flat file and bring back the leading edge of a rakers makes for a wild ride if you don't know what to expect but it works great in the bore cuts and project wood work like pockets for benches. But kick back is to be expected if the bar is burried.If you do a lot of bore cuts like I do you learn to keep your rakers angled. Vertical bore cuts will test how well your chain is tuned, I use them when cutting jack seats.. Also keep your gullets clean as your teeth get shorter. I also will thin rakers at the top from the side to reduce drag. Seems to help when when running 60cc and below saws with 3/8ths. If you run them at .030 or shorter be extra careful from kick back. Dangerous and hard on the main bearings and sprocket tip.

Fullskip

I still have all my body parts so it's all good