You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The possible factory issue with 026's?

- Thread starter TJ the Chainsaw Mechanic

- Start date

- Local time

- 6:53 AM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,614

- Reaction score

- 63,340

- Location

- Strong Island NY

Interesting observation.

I've had issues with them loading up at idle, but never with the tilting forward issue.

The saw with the worst loading up issue was one with a completely rounded intake opening interestingly enough, no square side wall.

By loading up, I mean getting them to work totally fine until I let them sit idling for more then 20 seconds and then getting a hesitation when pulling the trigger. Let them sit for 5-10 seconds and no hesitation occurs. It's always been the carb and maybe the coil.

When I blend my intakes, there's no ridge left by the cylinder and the opening to the port is matched or larger than the boot opening.

I guess I've been lucky.

I've had issues with them loading up at idle, but never with the tilting forward issue.

The saw with the worst loading up issue was one with a completely rounded intake opening interestingly enough, no square side wall.

By loading up, I mean getting them to work totally fine until I let them sit idling for more then 20 seconds and then getting a hesitation when pulling the trigger. Let them sit for 5-10 seconds and no hesitation occurs. It's always been the carb and maybe the coil.

When I blend my intakes, there's no ridge left by the cylinder and the opening to the port is matched or larger than the boot opening.

I guess I've been lucky.

- Local time

- 6:53 AM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,614

- Reaction score

- 63,340

- Location

- Strong Island NY

TJ the Chainsaw Mechanic

Old Homelites rule!

- Local time

- 3:53 AM

- User ID

- 433

- Joined

- Jan 7, 2016

- Messages

- 4,629

- Reaction score

- 8,975

- Location

- Next to my bench at the shop, Oregon

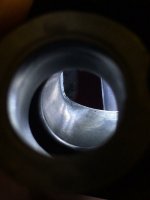

You can really see the lip on this one. This is what JD was talking about. Thing is though, if you were to clamp a manifold to it I am almost certain you'd be able to look down it and see a gap between the rubber and the metal. Great place for fuel to build up as well.

Simondo

Here For The Long Haul!

Your talking about the mid to top left part of the boot mating surface in the pic .... not any flashing or ridges further down the intake towards the piston ?

You can really see the lip on this one. This is what JD was talking about. Thing is though, if you were to clamp a manifold to it I am almost certain you'd be able to look down it and see a gap between the rubber and the metal. Great place for fuel to build up as well.

- Local time

- 6:53 AM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,614

- Reaction score

- 63,340

- Location

- Strong Island NY

I believe they are talking about the lip where the plating meets the cylinder. I wasn't sure what they meant either at first.

I guess any area that could catch charge at low speed could possibly cause a problem. The ridge by the cylinder wall makes the most sense.

Now I know what @jacob j. was saying about the 460. Some jugs have a terrible ridge by the bottom of the intake port by the cylinder wall. Removing it completely puts your intake opening well over 80*, it probably needs epoxy. There's actually a gully in the port before the plating rises up to meet the cylinder. Never seen it on a 44. Some 460/046 jugs, I believe the early and the later ones, don't have it.

The 046 jugs I've ground on have the most inconsistent intake port shapes of any OEM jugs I've encountered in my short time playing with saws. I sometimes wonder if the D chamber debate is more the intake port than the chamber itself. The port is offset, super thin on the bend by the flywheel side, and choppy on the PTO side as well. The worst ridge I've seen was in a mid year 046 with a hemi combustion chamber and plastic badge.

I guess any area that could catch charge at low speed could possibly cause a problem. The ridge by the cylinder wall makes the most sense.

Now I know what @jacob j. was saying about the 460. Some jugs have a terrible ridge by the bottom of the intake port by the cylinder wall. Removing it completely puts your intake opening well over 80*, it probably needs epoxy. There's actually a gully in the port before the plating rises up to meet the cylinder. Never seen it on a 44. Some 460/046 jugs, I believe the early and the later ones, don't have it.

The 046 jugs I've ground on have the most inconsistent intake port shapes of any OEM jugs I've encountered in my short time playing with saws. I sometimes wonder if the D chamber debate is more the intake port than the chamber itself. The port is offset, super thin on the bend by the flywheel side, and choppy on the PTO side as well. The worst ridge I've seen was in a mid year 046 with a hemi combustion chamber and plastic badge.

TJ the Chainsaw Mechanic

Old Homelites rule!

- Local time

- 3:53 AM

- User ID

- 433

- Joined

- Jan 7, 2016

- Messages

- 4,629

- Reaction score

- 8,975

- Location

- Next to my bench at the shop, Oregon

JD is talking about the ridges further down towards the plating near the piston. In the pic you can actually see a lip around that entire area.Your talking about the mid to top left part of the boot mating surface in the pic .... not any flashing or ridges further down the intake towards the piston ?

What I am noticing is when you hook a manifold to it, peaking down inside.... the Bottom of where they clamp seems to have a gap.

- Local time

- 3:53 AM

- User ID

- 232

- Joined

- Dec 24, 2015

- Messages

- 9,524

- Reaction score

- 65,929

- Location

- Coastal Oregon

As far as I know, Stihl never issued a SB on this, they just told us to handle it internally. Typically though, if corporate is going to reimburse the dealers for repair work, then an SB should be issued. Of course, the time period was same as when they were having multiple issues with the backpack blowers and the Kombi units and had already issued several service bulletins on those. I think as Al said, the issue was so sporadic and it really depended on the period of manufacture on the cylinders and the source.

TJ the Chainsaw Mechanic

Old Homelites rule!

- Local time

- 3:53 AM

- User ID

- 433

- Joined

- Jan 7, 2016

- Messages

- 4,629

- Reaction score

- 8,975

- Location

- Next to my bench at the shop, Oregon

I have Never had an 024, 026, 260 brought in with this complaint yet so I think that is why. When talking to JD he knew right away what the issue was, but it interests me why nothing was ever done. I guess not enough people complained about it.

- Local time

- 6:53 AM

- User ID

- 377

- Joined

- Jan 1, 2016

- Messages

- 19,499

- Reaction score

- 112,130

- Location

- Warren Center, PA

For the gap that you're talking about why couldn't you try a little yamabond or similar sealant to take up the gap? That is, if you still have the issue after removing the lip.JD is talking about the ridges further down towards the plating near the piston. In the pic you can actually see a lip around that entire area.

What I am noticing is when you hook a manifold to it, peaking down inside.... the Bottom of where they clamp seems to have a gap.

I've used it to seal some less than stellar designed intake boots like the J red 535 for instance.

Basher

Pinnacle OPE Member

- Local time

- 7:53 AM

- User ID

- 552

- Joined

- Jan 16, 2016

- Messages

- 1,351

- Reaction score

- 4,438

- Location

- Canada

This had the most loading issuesView attachment 58540

This is Daves 260

View attachment 58543

This one had none

View attachment 58545

Who made the cylinder in the top pict?

Simondo

Here For The Long Haul!

TJ.....might i suggest .....a saw brought in with the customer saying there is a problem is "perhaps" less frequent than the problem "actually" not being there .I have Never had an 024, 026, 260 brought in with this complaint yet so I think that is why. When talking to JD he knew right away what the issue was, but it interests me why nothing was ever done. I guess not enough people complained about it.

I can only speak about the saws that have been through my hands ...ether first being looked after by another shop..customer.. or never really having been serviced properly at all .

Most 024 and Ms 260 saws ( 026 very few) that have come to me have had a tendency to load up a bit....and most that have come to me were set (by others) to at least 3000-3100 rpm instead of the 2800 rpm Stihl say to use. I have found the higher idle along with a L set a tinny bit week helps to "mask" the load up from grounding the saw for 30 + seconds and then lifting it up with the bar pointing down. I have never got to grips with the reasons for this and just worked round it as best i could....in general going for 3000rpm and then allowing the saw to pull back to 2400-2500 rpm for the "short time" the saw is first picked up if the operator sets it down for any significant time. Iv used many of these saws for a test and have found if you are ether limbing or X cutting fairly constantly you don't notice the set down symptom.

My point being.....it may not be noticed by the average user or just not questioned as a fault "Unless" the saw dies out fully, but the tendency for the saw to have the symptom may still be there.

TJ the Chainsaw Mechanic

Old Homelites rule!

- Local time

- 3:53 AM

- User ID

- 433

- Joined

- Jan 7, 2016

- Messages

- 4,629

- Reaction score

- 8,975

- Location

- Next to my bench at the shop, Oregon

Ah makes sense, I keep having to remember that as a mechanic I get really picky on saw tuning. haha The last 026 I sent out I set the idle at 3K and leaned the Low end as much as I could with it still running decent. With the top end running a tad rich it seemed to work ok. Still loaded up a bit, but not as bad as before.TJ.....might i suggest .....a saw brought in with the customer saying there is a problem is "perhaps" less frequent than the problem "actually" not being there .

I can only speak about the saws that have been through my hands ...ether first being looked after by another shop..customer.. or never really having been serviced properly at all .

Most 024 and Ms 260 saws ( 026 very few) that have come to me have had a tendency to load up a bit....and most that have come to me were set (by others) to at least 3000-3100 rpm instead of the 2800 rpm Stihl say to use. I have found the higher idle along with a L set a tinny bit week helps to "mask" the load up from grounding the saw for 30 + seconds and then lifting it up with the bar pointing down. I have never got to grips with the reasons for this and just worked round it as best i could....in general going for 3000rpm and then allowing the saw to pull back to 2400-2500 rpm for the "short time" the saw is first picked up if the operator sets it down for any significant time. Iv used many of these saws for a test and have found if you are ether limbing or X cutting fairly constantly you don't notice the set down symptom.

My point being.....it may not be noticed by the average user or just not questioned as a fault "Unless" the saw dies out fully, but the tendency for the saw to have the symptom may still be there.

SteveSr

Well-Known OPE Member

- Local time

- 6:53 AM

- User ID

- 2294

- Joined

- Dec 14, 2016

- Messages

- 142

- Reaction score

- 103

- Location

- North Carolina

Hello,

So I wasn't loosing my mind! Bought a late 026 and it had this issue. Dealer couldn't reproduce/fix it so I finally sent a letter to the head of Stihl USA and they bought the saw back.

Got a new 260 Pro to replace the 026 and after it was broken in it exhibited the same issue! Called Stihl and they said it was a carb issue and authorized putting the older adjustable (I think WT-426) on it. This fixed it. as I recall the problematic carb was the fixed "H" jet WT-403. I have since seen this behavior on several 026/260s with the 403 carb on it.

So I wasn't loosing my mind! Bought a late 026 and it had this issue. Dealer couldn't reproduce/fix it so I finally sent a letter to the head of Stihl USA and they bought the saw back.

Got a new 260 Pro to replace the 026 and after it was broken in it exhibited the same issue! Called Stihl and they said it was a carb issue and authorized putting the older adjustable (I think WT-426) on it. This fixed it. as I recall the problematic carb was the fixed "H" jet WT-403. I have since seen this behavior on several 026/260s with the 403 carb on it.

Adirondackstihl

Vert Da Furk........Bork Bork Bork

- Local time

- 6:53 AM

- User ID

- 17

- Joined

- Dec 4, 2015

- Messages

- 5,926

- Reaction score

- 25,664

- Location

- Upstate NY

Next time any of you guys have an 031 on the bench, pull the carb and look at THAT mess!!

I got pics somewhere. Lemme see if I can find em.

I got pics somewhere. Lemme see if I can find em.

Adirondackstihl

Vert Da Furk........Bork Bork Bork

- Local time

- 6:53 AM

- User ID

- 17

- Joined

- Dec 4, 2015

- Messages

- 5,926

- Reaction score

- 25,664

- Location

- Upstate NY

- Local time

- 12:53 PM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,505

- Reaction score

- 57,576

- Location

- Croatia

That's what the Chinese didn't wanna sell as AM parts so Stihl bought them and sold them as factory OEM!BEFOREView attachment 117024

Colored with a Sharpie...View attachment 117026

AFTER

View attachment 117025

Good enough for whom it's for?

jakethesnake

I Am The Snake

- Local time

- 6:53 AM

- User ID

- 786

- Joined

- Feb 5, 2016

- Messages

- 7,740

- Reaction score

- 20,569

- Location

- Here & Now

Dirty stihl

Adirondackstihl

Vert Da Furk........Bork Bork Bork

- Local time

- 6:53 AM

- User ID

- 17

- Joined

- Dec 4, 2015

- Messages

- 5,926

- Reaction score

- 25,664

- Location

- Upstate NY

It was a fairly dirty specimen, yes.Dirty stihl

But it left here spotless....almost like the day it left the dealership