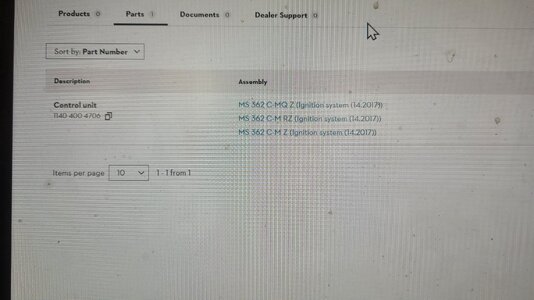

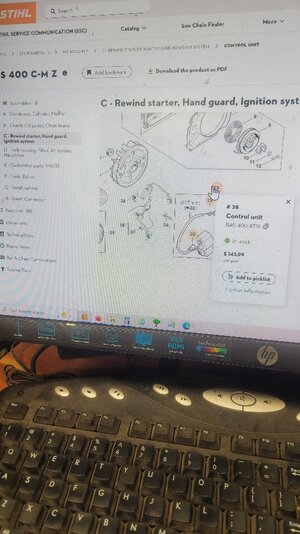

Well Stihl, you kicked my ass today. After setting aside my 261c for a potential solenoid replacement, I pulled out a grungy 039 that needs some love.

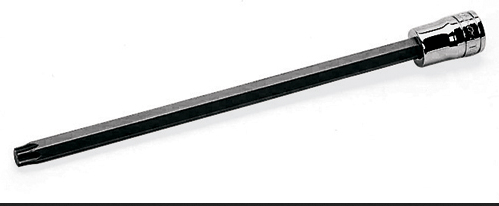

Got it nearly fully disassembled, with just the engine bolts to remove. Wow, what a pain in the arse these things are... Bent up two Stihl brand torx screnches, broke one off in the t27 screw, and started to strip out a remaining one... Not sure how the hell I can get these things out, since they're burried into the crankcase.

Open to any advice on gettin' these out. I tried penetrating oil, as well as putting a soldering iron on the bolt head for a few minutes, with no luck.

Bottom right has a tip broken off flush in the torx head, and top left is starting to round out. The other two have been freed up