You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

STIHL The Official Stihl Chainsaws Thread

- Thread starter Greenthorn

- Start date

Woodslasher

Teh debil

- Local time

- 10:29 AM

- User ID

- 15993

- Joined

- Mar 18, 2021

- Messages

- 3,733

- Reaction score

- 15,282

- Location

- Commiefornia

Nope. From what I heard all the 461’s (or at least all the ones with Gilardoni jugs) are more susceptible to stripped plug threads than other saws.Is there a range of serial numbers for 461s that are affected?

spencerdiesel

Well-Known OPE Member

- Local time

- 1:29 PM

- User ID

- 14124

- Joined

- Oct 10, 2020

- Messages

- 98

- Reaction score

- 164

- Location

- Brevard, NC

Thanks for letting me know you all! I’ll be taking it in for them to attempt removing it. Good thing I haven’t even fueled or oiled it

PogoInTheWoods

Pinnacle OPE Member

- Local time

- 1:29 PM

- User ID

- 1190

- Joined

- Apr 23, 2016

- Messages

- 1,957

- Reaction score

- 3,908

- Location

- Ohio

From what I heard...

See, that's the kind of hearsay stuff that drives me nuts! LOL I've never heard anything at all about bad plug threads on 461s -- from my go-to dealer who sold a truckload of em, or anyone else for that matter. And I've worked on quite a few myself.

I do personally know plenty of *pretty boyes crankin' the piss outta spark plugs and strippin' the threads in all kinds of other saws, though. LOL

spencerdiesel

Well-Known OPE Member

- Local time

- 1:29 PM

- User ID

- 14124

- Joined

- Oct 10, 2020

- Messages

- 98

- Reaction score

- 164

- Location

- Brevard, NC

RI Chevy, I am unfortunately of the category “exceedingly curious” and want to know what everything looks like on the inside. I’m glad I did try to remove the plug, at least I (hopefully) have a chance at warranty if the dealer can’t pull it or it strips on the way out.

Maintenance Chief

Disrupting the peace with an old chainsaw

- Local time

- 1:29 PM

- User ID

- 11378

- Joined

- Jan 4, 2020

- Messages

- 4,215

- Reaction score

- 13,788

- Location

- South Carolina

Two of the prominent proters on here mentioned it and had some pictures, one who only does new saws.

spencerdiesel

Well-Known OPE Member

- Local time

- 1:29 PM

- User ID

- 14124

- Joined

- Oct 10, 2020

- Messages

- 98

- Reaction score

- 164

- Location

- Brevard, NC

Does anyone know if Stihl ever remedied this? I’m taking the saw in to my dealer tomorrow.

I did specifically ask for this ms461 because it was NIB. The other two they had were on display. I wonder if that will end up looking funny on my end…..

I did specifically ask for this ms461 because it was NIB. The other two they had were on display. I wonder if that will end up looking funny on my end…..

PogoInTheWoods

Pinnacle OPE Member

- Local time

- 1:29 PM

- User ID

- 1190

- Joined

- Apr 23, 2016

- Messages

- 1,957

- Reaction score

- 3,908

- Location

- Ohio

Two of the prominent proters on here mentioned it and had some pictures,

Link?

Woodslasher

Teh debil

- Local time

- 10:29 AM

- User ID

- 15993

- Joined

- Mar 18, 2021

- Messages

- 3,733

- Reaction score

- 15,282

- Location

- Commiefornia

https://opeforum.com/threads/buggered-plug-threads.24489/See, that's the kind of hearsay stuff that drives me nuts! LOL I've never heard anything at all about bad plug threads on 461s -- from my go-to dealer who sold a truckload of em, or anyone else for that matter. And I've worked on quite a few myself.

I do personally know plenty of *pretty boyes crankin' the piss outta spark plugs and strippin' the threads in all kinds of other saws, though. LOL

PogoInTheWoods

Pinnacle OPE Member

- Local time

- 1:29 PM

- User ID

- 1190

- Joined

- Apr 23, 2016

- Messages

- 1,957

- Reaction score

- 3,908

- Location

- Ohio

So there ya go. It's official.

If there was a T.I. (tech note/bulletin) released, your dealer should certainly know about it. I don't see one in the documentation currently at my disposal. Then again, I didn't see one for the change from the D cylinder to the hemi on the 046s, either. My guess there is one was never released since it wasn't a problem or obvious design change worthy of publication. Faulty cylinders would be a different story altogether -- and a problem Stihl would want dealers to keep quiet about unless seriously pressed by a customer for a warranty claim.

Be honest with your dealer and expect the same in return. But don't accept a faulty cylinder on a brand new saw.

Does anyone know if Stihl ever remedied this?

If there was a T.I. (tech note/bulletin) released, your dealer should certainly know about it. I don't see one in the documentation currently at my disposal. Then again, I didn't see one for the change from the D cylinder to the hemi on the 046s, either. My guess there is one was never released since it wasn't a problem or obvious design change worthy of publication. Faulty cylinders would be a different story altogether -- and a problem Stihl would want dealers to keep quiet about unless seriously pressed by a customer for a warranty claim.

Be honest with your dealer and expect the same in return. But don't accept a faulty cylinder on a brand new saw.

spencerdiesel

Well-Known OPE Member

- Local time

- 1:29 PM

- User ID

- 14124

- Joined

- Oct 10, 2020

- Messages

- 98

- Reaction score

- 164

- Location

- Brevard, NC

Great points thank you. I’ll just be up front (candor I believe the term is) and polite tomorrow, we’ll see.

By the way, how does the exhaust scavenging work on a 461? Is it basically just really short blowdown that pushes exhaust back towards/ into the transfers?

How much is that changed going from stock to a DP muffler cover?

By the way, how does the exhaust scavenging work on a 461? Is it basically just really short blowdown that pushes exhaust back towards/ into the transfers?

How much is that changed going from stock to a DP muffler cover?

PogoInTheWoods

Pinnacle OPE Member

- Local time

- 1:29 PM

- User ID

- 1190

- Joined

- Apr 23, 2016

- Messages

- 1,957

- Reaction score

- 3,908

- Location

- Ohio

how does the exhaust scavenging work on a 461? Is it basically just really short blowdown that pushes exhaust back towards/ into the transfers?

Pretty much. Changing the muffler cover shouldn't change how that works except making the whole process more efficient as additional intake air is introduced by the increased flow overall. At least that's how I interpret how it would work.

I just rebuilt a 461 with a BarkBox on it for a logger. He bought it from some rich kid firewood guy who just had to have a 500i. 461 was like new. $600 Ran like $hit. Pulled the limiters, re-tuned and it screamed with superb response. No porting involved. Just a lot more air flow.

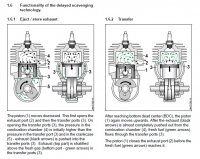

Here's an illustration for understanding how the 461 is laid out. The PDF offers a bit more info.

Attachments

spencerdiesel

Well-Known OPE Member

- Local time

- 1:29 PM

- User ID

- 14124

- Joined

- Oct 10, 2020

- Messages

- 98

- Reaction score

- 164

- Location

- Brevard, NC

Thanks for the great read! So the dealer got the plug out, that thing had to be over 40 ft lbs……he’s a big guy and he had to take two tries at it. I’m amazed that the threads are seemingly perfect, and tickled he snugged the plug with finesse.

I noticed this saw has had some amount of run time on it from the factory (unfortunately). Will these “bedding” streaks go away with load and time?

I noticed this saw has had some amount of run time on it from the factory (unfortunately). Will these “bedding” streaks go away with load and time?

Attachments

president

Super OPE Member

- Local time

- 10:29 AM

- User ID

- 14155

- Joined

- Oct 12, 2020

- Messages

- 293

- Reaction score

- 496

- Location

- peachland BC Canada

isn;t the high comp metal gasket .5mill?I'm interested in the source of your information..., not doubting you to be a dick. Just curious since my 046 knowledge isn't very broad, though it's basically just a big bore 044.

Such a change would typically be indicated by a specific serial number break point and a corresponding and dated tech note. I can't find one specifically indicating any cylinder design changes you're referring to except maybe the widening of the intake port (and changing the ring locating pin locations to accommodate it) in TI_44_2000. This was early in the 1 48 *** *** serial number range in 2000.

That said, there was a "low compression" configuration (primarily for third world countries and *s-wordty gas) that used an .8mm base gasket. Simply dropping that to the normal .3mm gasket would certainly affect timing to an extent, and obviously compression.

PogoInTheWoods

Pinnacle OPE Member

- Local time

- 1:29 PM

- User ID

- 1190

- Joined

- Apr 23, 2016

- Messages

- 1,957

- Reaction score

- 3,908

- Location

- Ohio

that thing had to be over 40 ft lbs

So much for the wimpy plug threads in 461 cylinders. And that cylinder doesn't look right to me. Should be nothing but clean cross hatch on the walls and the exhaust port looks to have a very uneven finish. That said, I'd say it's good you took pics now in case there are other issues not immediately obvious.

I'd be keeping my fingers crossed -- or take the saw back again and do some serious comparisons with the other ones the dealer has on hand. The plug should never have been that tight, so..., who knows what else may be going on with it? Better to find out now while the issues are new than after it's been run awhile.

Last edited:

PogoInTheWoods

Pinnacle OPE Member

- Local time

- 1:29 PM

- User ID

- 1190

- Joined

- Apr 23, 2016

- Messages

- 1,957

- Reaction score

- 3,908

- Location

- Ohio

isn;t the high comp metal gasket .5mill?

0.3mm for the normal base gasket on a 046.

spencerdiesel

Well-Known OPE Member

- Local time

- 1:29 PM

- User ID

- 14124

- Joined

- Oct 10, 2020

- Messages

- 98

- Reaction score

- 164

- Location

- Brevard, NC

Yes sir I agree. I hate to look like a nuisance to this dealer but sometimes it’s just what it is. I’ll give them a call 1st

PogoInTheWoods

Pinnacle OPE Member

- Local time

- 1:29 PM

- User ID

- 1190

- Joined

- Apr 23, 2016

- Messages

- 1,957

- Reaction score

- 3,908

- Location

- Ohio

What's the serial number of the saw?

Similar threads

- Replies

- 49

- Views

- 1K