heavy_oil_saw

Well-Known OPE Member

- Local time

- 3:03 AM

- User ID

- 11623

- Joined

- Feb 2, 2020

- Messages

- 37

- Reaction score

- 116

- Location

- Colchester

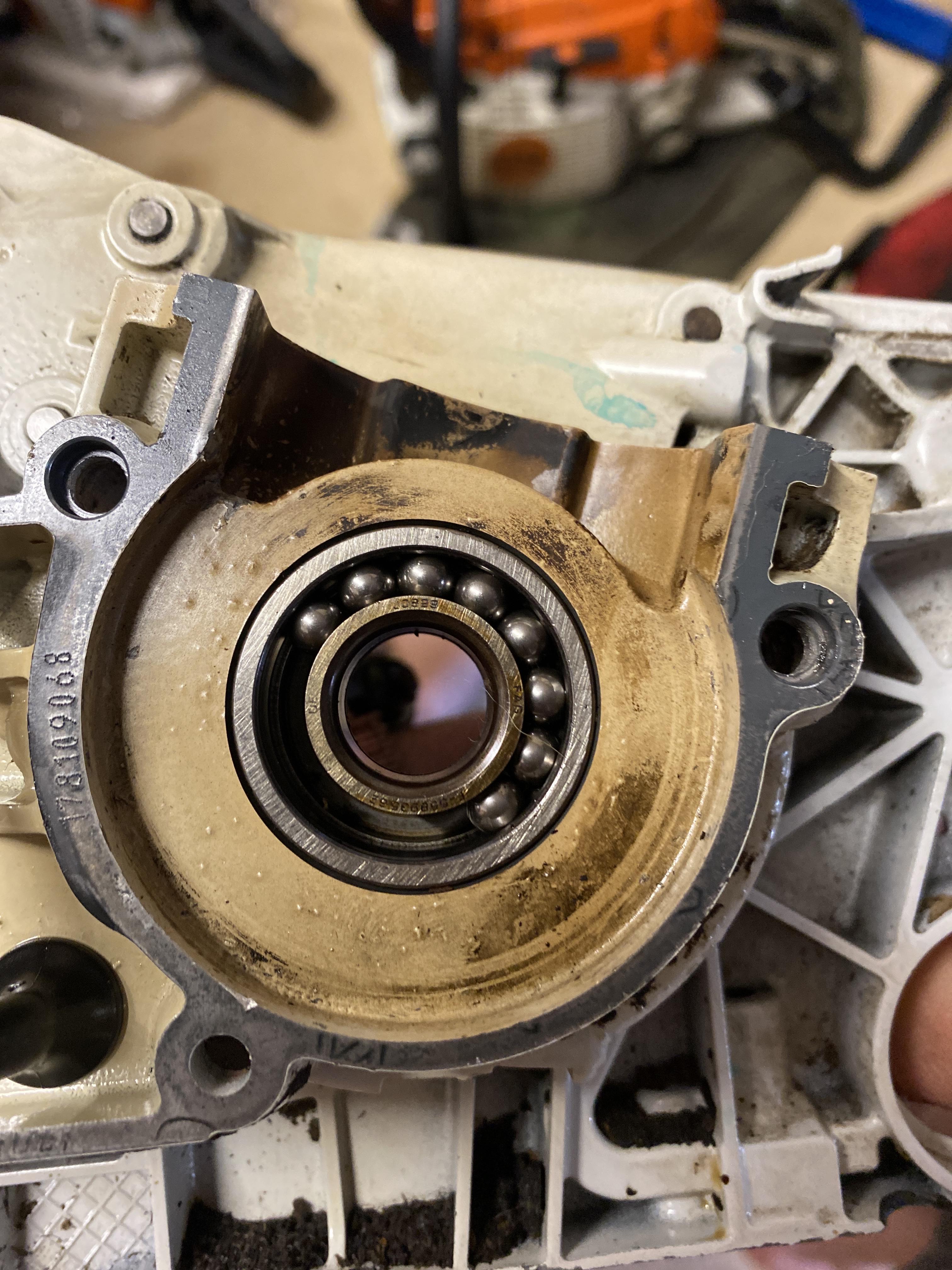

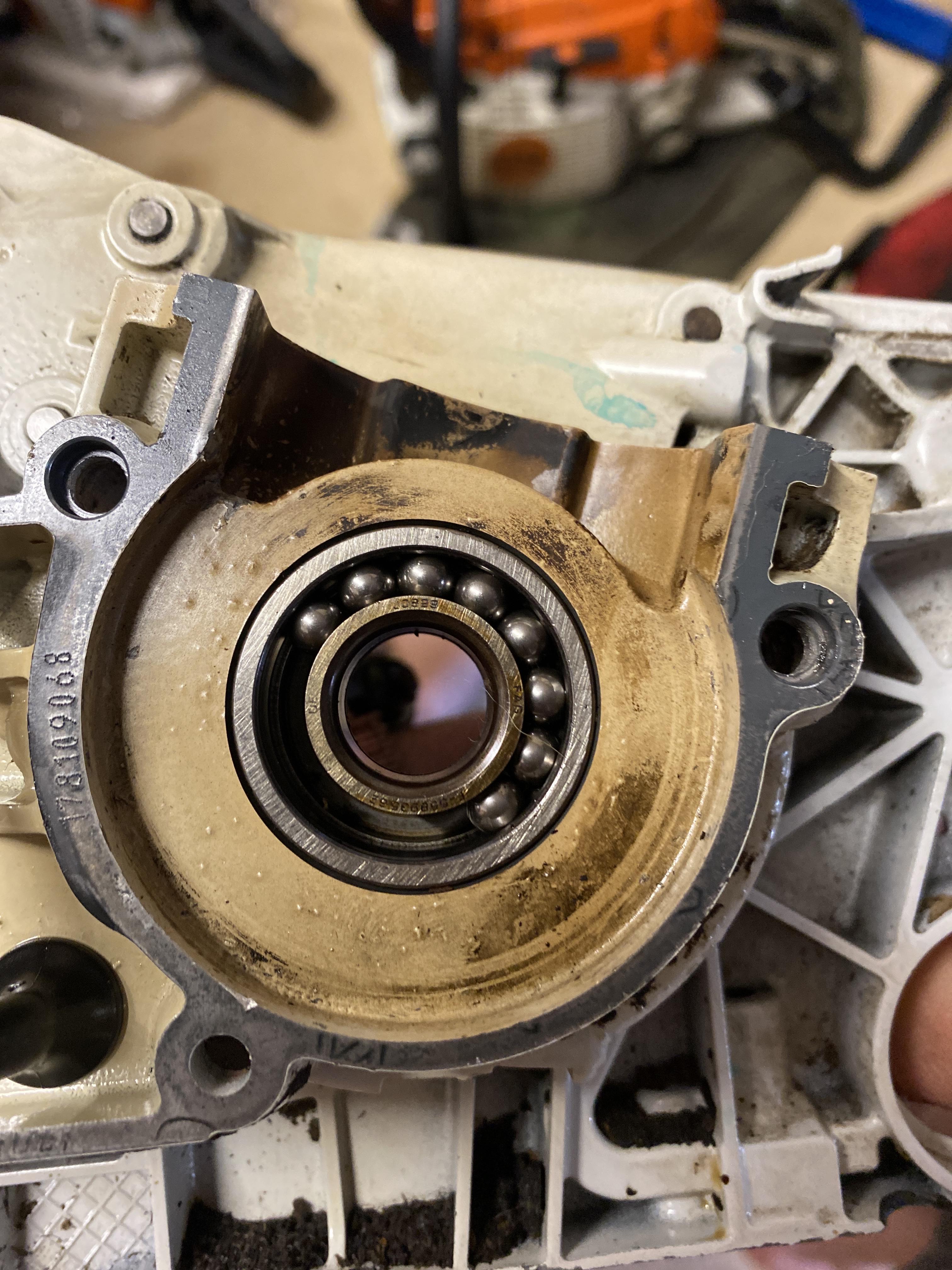

Buy the time I’d started building the saw, I discovered the crankshaft problem. Lots of ideas, 1)incorrect surface hardness of crank so the bearing which is harder eats the crank, 2)incorrectly aligned crankcases at factory, causing throw out at the end, then wearing out the stub end, 3)lack of greasing of the bearing, these are the main 3 beliefs I’ve found (non are concrete though).

On the other hand, common believe is MT cranks are fine and no reports of wear, though I bought a MT crank case and the crank was shot big time, the flywheel had smashed the crank case, eaten the oil pump and destroyed the oil pump side crank case bearing.

Standard measurement is 10mm, once you get below that by a couple of thou and the crank is on a downwards spiral to destruction.

Finger for reference.

Real problem is, there is no hard or fast rule, some carb models, no problem at all, run hard, little or no maint and the crank is A OK, some out the box and babyfied, crank dead in no time, some MT versions obviously suffer from this crank problem as well. Luck of the draw, and Stihl ain’t saying a thing.

Sent from my iPhone using Tapatalk

On the other hand, common believe is MT cranks are fine and no reports of wear, though I bought a MT crank case and the crank was shot big time, the flywheel had smashed the crank case, eaten the oil pump and destroyed the oil pump side crank case bearing.

Standard measurement is 10mm, once you get below that by a couple of thou and the crank is on a downwards spiral to destruction.

Finger for reference.

Real problem is, there is no hard or fast rule, some carb models, no problem at all, run hard, little or no maint and the crank is A OK, some out the box and babyfied, crank dead in no time, some MT versions obviously suffer from this crank problem as well. Luck of the draw, and Stihl ain’t saying a thing.

Sent from my iPhone using Tapatalk

Last edited: