You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stihl 362 C-M scored piston

- Thread starter Travis-Mc

- Start date

Cobby08

I’m a face down ass up guy

- Local time

- 12:58 PM

- User ID

- 302

- Joined

- Dec 28, 2015

- Messages

- 1,051

- Reaction score

- 4,170

- Location

- Central New Yawk...

Not 100% on your question but I assume you are asking if BOTH happen at the same time, it would be just like any other saw. It would probably lean seize/score. The MT/AT systems aren't really designed to compensate really for poor lubrication.

Cobby08

I’m a face down ass up guy

- Local time

- 12:58 PM

- User ID

- 302

- Joined

- Dec 28, 2015

- Messages

- 1,051

- Reaction score

- 4,170

- Location

- Central New Yawk...

I guess malfunction wise yes it could. I am not sure about the AT but I know the solenoid on the MT is a normally open solenoid so if there is a failure its just going to flood the chit out of it.

- Local time

- 11:58 AM

- User ID

- 1799

- Joined

- Sep 4, 2016

- Messages

- 2,437

- Reaction score

- 9,961

- Location

- Wisconsin

I bought my first "pro" saw a few months ago, a used MS362 carb version.

I buck with it, leaving it at 3/4 throttle or more for 5 mins or so, just moving down the hardwood logs and letting it self feed.

I may spend an hour like this.

I mix stihl orange bottle at 40:1 with non ethanol fuel.

This thread has me all worried.

I'm going to inspect the piston tonight.

I bought it to treat as a professional grade tool that would save me time.

This would really sour me on Stihl if I cant use it without worry of it getting damaged by normal use.

I'm with cobby08 on this one. Idle or WOT. No partial throttle.

- Local time

- 12:58 PM

- User ID

- 360

- Joined

- Dec 31, 2015

- Messages

- 23,529

- Reaction score

- 150,466

- Location

- East Jordan, MI

I guess that's another reason to dislike limited coils. If a guy listens for 4 stroking in between every few cuts, he's normally safe. Can't do so with a limited coil

Travis-Mc

OPE Member

- Local time

- 11:58 AM

- User ID

- 7792

- Joined

- Nov 6, 2018

- Messages

- 10

- Reaction score

- 10

- Location

- Wisconsin

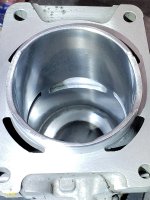

I got the cylinder all cleaned up. It cleaned up nicely. I did hit the top of the chamber with the end of my mandrel, but I don't think it'll affect anything. You can see it in one of the pictures and in a reflection off the cylinder wall.

The squish with the new piston is about .010 without a gasket, .025 with the oem gasket, and .015 with a pop can gasket. I was hoping for .018", so I'm thinking of either making another gasket from some .008 aluminum, or cutting .008" from the piston to make a pop-up piston. Is it worth trying a pop-up for only .008" removed? I have a lathe and it would only take a few minutes.

Should I just use the OEM gasket? From my calculations, using an .008 gasket instead of the oem one will decrease the combustion chamber size by about 4-5%. Maybe I'm doing the math wrong, but I would expect about a 4-5% increase in compression, so 6-7 psi. Is it even worth it for that? Does a 4-5% increase in compression mean 4-5% more power?

Now if I do a pop-up piston I should get quite a bit more gain in compression, but I have no idea how much and don't want to do any more math.

The squish with the new piston is about .010 without a gasket, .025 with the oem gasket, and .015 with a pop can gasket. I was hoping for .018", so I'm thinking of either making another gasket from some .008 aluminum, or cutting .008" from the piston to make a pop-up piston. Is it worth trying a pop-up for only .008" removed? I have a lathe and it would only take a few minutes.

Should I just use the OEM gasket? From my calculations, using an .008 gasket instead of the oem one will decrease the combustion chamber size by about 4-5%. Maybe I'm doing the math wrong, but I would expect about a 4-5% increase in compression, so 6-7 psi. Is it even worth it for that? Does a 4-5% increase in compression mean 4-5% more power?

Now if I do a pop-up piston I should get quite a bit more gain in compression, but I have no idea how much and don't want to do any more math.

Attachments

MustangMike

Mastermind Approved!

- Local time

- 12:58 PM

- User ID

- 338

- Joined

- Dec 30, 2015

- Messages

- 11,546

- Reaction score

- 36,440

- Location

- Brewster, NY

May want to try some flashing, usually about .010.

Travis-Mc

OPE Member

- Local time

- 11:58 AM

- User ID

- 7792

- Joined

- Nov 6, 2018

- Messages

- 10

- Reaction score

- 10

- Location

- Wisconsin

That's exactly what I thinking. $5 for whole roll and I'll only need a few inches. I was going to lightly sand it to see if I could get it to .008"

But now I'm leaning toward running no gasket and doing the small pop-up. Not sure yet.

But now I'm leaning toward running no gasket and doing the small pop-up. Not sure yet.

- Local time

- 12:58 PM

- User ID

- 360

- Joined

- Dec 31, 2015

- Messages

- 23,529

- Reaction score

- 150,466

- Location

- East Jordan, MI

I'd run it with the OEM gasket. I don't think you're going to be able to feel the difference by only removing a half of a gasket in squish clearance. You did a nice job cleaning up your cylinder. That looks really good

shadco

Ban Hammer Custodian

- Local time

- 12:58 PM

- User ID

- 8089

- Joined

- Dec 10, 2018

- Messages

- 1,325

- Reaction score

- 8,263

- Location

- City of Oaks, NC

Doesn’t cost much to try it with the stock gasket less risk too. You can always go thinner later.

.

.

Travis-Mc

OPE Member

- Local time

- 11:58 AM

- User ID

- 7792

- Joined

- Nov 6, 2018

- Messages

- 10

- Reaction score

- 10

- Location

- Wisconsin

Well that sounds like the safe thing to do, but where's the fun in that?  I thought for sure you guys would say go for the pop-up, and you might as well port it a little while you're in there!

I thought for sure you guys would say go for the pop-up, and you might as well port it a little while you're in there!

Once I have it back together, I doubt I'll take it apart again unless I have to.

I just got a 261 c-m, and would really like a 462 c-m instead of this saw, but I really don't need it, so I like the idea of trying to mod this saw a little so it doesn't just have .7 more hp than my small saw. But maybe you're right, use a stock gasket and a muffler mod that can easily be undone in case I decide to sell it. I'm on the fence.

Once I have it back together, I doubt I'll take it apart again unless I have to.

I just got a 261 c-m, and would really like a 462 c-m instead of this saw, but I really don't need it, so I like the idea of trying to mod this saw a little so it doesn't just have .7 more hp than my small saw. But maybe you're right, use a stock gasket and a muffler mod that can easily be undone in case I decide to sell it. I'm on the fence.

Similar threads

- Replies

- 39

- Views

- 5K