Here's mine. Just finished it up at the shop and towed it home last night.

Specs are:

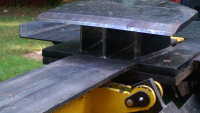

W8x24 wide flange beam, set up to do vertical and horizontal work with a work table for horizontal. 1.25" plate foot.

6x6x.125 axle/hydraulic reservoir comes out to about 7.5 gallons of fluid. 4.80x12 wheel/tire

Hand built wedge with 1/2" base plate and flare plates, 3/4" main wedge

3x3 .125 tongue with 2"ball coupler. 2000lb bulldog top wind pivoting jack

4x24 cylinder mated to a 13gpm 2 stage pump. Math calculates 18.855 true tons at 3000psi not some made up number like the ones they sell at lowes or tsc. 1" supply line, 3/4" pressure line from pump to valve and 1/2" work ports and hoses/lines. Should come out to a true unloaded cycle time of about 11.2 seconds 24" out and back.

Predator 212cc engine

All parts drawn/programmed/cut/fabricated/welded by me

-Scott