You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Real talk about saw porting theory (no arguments)

- Thread starter EvilRoySlade

- Start date

-

- Tags

- good porting thread

- Local time

- 9:08 AM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,614

- Reaction score

- 63,341

- Location

- Strong Island NY

Not 100% true. I wanna start by saying I'm not singling you out Peter, it's just a common misconception I used to believe as well.from what ive read about porting it takes awhile to perfect it , thats why people send there saws to some one like Randy , to get it done correctly , now if people start doing video,s and numbers of how the ported a saw , it could take money away from guys that make a living out of it

you can ask question about porting and get some ideas and if you have a go , only if its a little bit , and post pics , im sure you will get the advise you need to make it right , theres a lot on youtube also

im only learning myself and find the guys very helpful if i wont to have a crack at it

Peter

I'm new to the game and have been given advise by Mastermind, Jason, Brad, Mike Lee, Tree Monkey and Rattler to name a few. Sorry if I left anyone out.

The more you do it, the more you start to realize you can show anyone and tell anyone what you are doing and it won't matter. Trade secrets are kept, but usually are more secretive between the pro's that can use them than the average guy.

Yes, the guys that give advice are being generous and honest, but they also realize it won't hurt them.

If I explain how to do open heart surgery to you exactly and step by step, do you think you could do it? Think anyone would have you do it to them? Ever have to redo a repair on a car and realize that the second and third time you took it apart you kept doing it better and faster?

I'd also add that once you learn how to do it, then realize how much time it takes and how expensive it is in material to do one saw, you question whether or not you should just send saws out to be done by another.

With that out of the way, I'd be glad to help and share what I've come to learn. I won't get buthurt if one of the pro's steps in and tells me I'm wrong. I'll take any criticism, as long as it's constructive.

I'm gonna tty to say how I do each saw step by step.

- Local time

- 9:08 AM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,614

- Reaction score

- 63,341

- Location

- Strong Island NY

I start every build with the stock numbers. I measure them unless I know them already.

Then I check stock squish. With most saws I go base gasket delete because I get to leave that extra .020+ on the jug base for strength. It's a pita to do and to pull jug if needed, but it's worth it. Some saws, like the Stihl 044/046, are thick enough to leave the base gasket on.

I check stock compression. If a saw is 180 psi stock, I know that I can't move the band too much. I determine the compression bump I want by the cc of the saw. Big saws can't cool as effectivelay as smaller bore saws, so they get less compression.

My own personal rule is 45-55 cc max comp of 250ish, 55-65 230, 65-75 210, 75-85 200, 85+ 190ish. Again, personal rule. How do you predict it? Guesstimate and trial and error. Keep notes.

Then I check stock squish. With most saws I go base gasket delete because I get to leave that extra .020+ on the jug base for strength. It's a pita to do and to pull jug if needed, but it's worth it. Some saws, like the Stihl 044/046, are thick enough to leave the base gasket on.

I check stock compression. If a saw is 180 psi stock, I know that I can't move the band too much. I determine the compression bump I want by the cc of the saw. Big saws can't cool as effectivelay as smaller bore saws, so they get less compression.

My own personal rule is 45-55 cc max comp of 250ish, 55-65 230, 65-75 210, 75-85 200, 85+ 190ish. Again, personal rule. How do you predict it? Guesstimate and trial and error. Keep notes.

- Local time

- 9:08 AM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,614

- Reaction score

- 63,341

- Location

- Strong Island NY

I'm gonna use a 60cc saw for example, the Stihl 036.

So then you've got the squish to measure. So I do so with the predetermined plan to run a gasket or not.

So measuring with or sans gasket, I get my measurement. On the saw that will be ported.

So the average 036 measure about .014 squish sans gasket. Add a band cut of .040 to that, you get .054 squish. Take .034 Off the base and you're back at 20 squish.

Then I always use a builder case when possible with the jug and piston to be used on the saw. Make two threaded dowel pins for the builder case and put in diagonally at the case base.

Using a mandel, I start cutting the bands. You also need to have a mandrel to sand with. One can use a lathe for the entire cutting, like Randy does, but I find it easier to use a mandrel. Probably ignorance and fear on my part.

I use the same mandrel that I spin the base cut on as a sander. An old piston can be used as well.

Cut the band and sand any unevenness out as you go. Sticky backed sandpaper cut around the mandrel works great.

Put the jug over the piston on the builder case and rotate the saw. Keep cutting till the piston can freely rotate and isn't head slapping. Intermittently, slide some very thin solder between the piston and the band through the plug hole at TDC. Make sure it cans slide in if the piston can't be rotated. If it can, you've got a ridge that had to be removed before you go any further.

I scrape the ridge out of all of my builds with a wood chisel on an angle. Yes, a wood chisel. It's good to get into the habit of doing it intermittently as you cut the band.

Once the piston can freely rotate, you need to add two cylinder bolts and mount the jug firmly to the case. Now check squish with .023 solder. See what you get. Sneak up on .020-023.

It's time consuming.

So then you've got the squish to measure. So I do so with the predetermined plan to run a gasket or not.

So measuring with or sans gasket, I get my measurement. On the saw that will be ported.

So the average 036 measure about .014 squish sans gasket. Add a band cut of .040 to that, you get .054 squish. Take .034 Off the base and you're back at 20 squish.

Then I always use a builder case when possible with the jug and piston to be used on the saw. Make two threaded dowel pins for the builder case and put in diagonally at the case base.

Using a mandel, I start cutting the bands. You also need to have a mandrel to sand with. One can use a lathe for the entire cutting, like Randy does, but I find it easier to use a mandrel. Probably ignorance and fear on my part.

I use the same mandrel that I spin the base cut on as a sander. An old piston can be used as well.

Cut the band and sand any unevenness out as you go. Sticky backed sandpaper cut around the mandrel works great.

Put the jug over the piston on the builder case and rotate the saw. Keep cutting till the piston can freely rotate and isn't head slapping. Intermittently, slide some very thin solder between the piston and the band through the plug hole at TDC. Make sure it cans slide in if the piston can't be rotated. If it can, you've got a ridge that had to be removed before you go any further.

I scrape the ridge out of all of my builds with a wood chisel on an angle. Yes, a wood chisel. It's good to get into the habit of doing it intermittently as you cut the band.

Once the piston can freely rotate, you need to add two cylinder bolts and mount the jug firmly to the case. Now check squish with .023 solder. See what you get. Sneak up on .020-023.

It's time consuming.

Last edited:

- Local time

- 9:08 AM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,614

- Reaction score

- 63,341

- Location

- Strong Island NY

When you're finally done, you gotta wash the jug and piston thoroughly, ending with soap and water, to get any metal debris off of it.

Then mount to the actual saw and check squish. Measure any difference between the saw and the builder case. Then redo steps above until the desired squish is cut. So if you're at .018 on your builder case and only .014 on the actual saw, cut the band to .024 on the builder case. Just make sure you measure twice and cut once. You can't add the material you cut out back.

Then mount to the actual saw and check squish. Measure any difference between the saw and the builder case. Then redo steps above until the desired squish is cut. So if you're at .018 on your builder case and only .014 on the actual saw, cut the band to .024 on the builder case. Just make sure you measure twice and cut once. You can't add the material you cut out back.

- Local time

- 9:08 AM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,614

- Reaction score

- 63,341

- Location

- Strong Island NY

cease232

Pinnacle OPE Member

- Local time

- 9:08 AM

- User ID

- 1443

- Joined

- Jun 20, 2016

- Messages

- 524

- Reaction score

- 1,733

- Location

- Montana

Make two threaded dowel pins for the builder case and put in diagonally at the case base.

Make sure it cans slide in if the piston can't be rotated. If it can, you've got a ridge that had to be removed before you go any further.

Doc can you expand on these two points, I'm not quite getting what your referring to. Pics if you got em. Thank you for doing this!

- Local time

- 9:08 AM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,614

- Reaction score

- 63,341

- Location

- Strong Island NY

- Local time

- 9:08 AM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,614

- Reaction score

- 63,341

- Location

- Strong Island NY

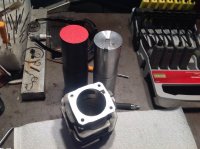

Cut heads off two jug to case bolts. Grind sharp edges off. Thread in diagonally across from each other.Doc can you expand on these two points, I'm not quite getting what your referring to. Pics if you got em. Thank you for doing this!

That way you can slip the jug on and off the builder case and hold it down by hand for timing measurements.

Otherwise you have to screw two bolts in every time u need to take a measurement, which sux.

I'll see if I got a pic.

- Local time

- 9:08 AM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,614

- Reaction score

- 63,341

- Location

- Strong Island NY

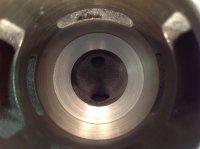

Here's @cus_deluxe 262. There's a pin hiding behind the piston.

I always use a builder case when possible. Much faster because you can be assured no metal particles get into the final saw. I've found that blowing out the jug with compressed air each time isn't enough to get all the junk out. I always put it in the USC and then hand wash and dry before it touches the final saw.

I always use a builder case when possible. Much faster because you can be assured no metal particles get into the final saw. I've found that blowing out the jug with compressed air each time isn't enough to get all the junk out. I always put it in the USC and then hand wash and dry before it touches the final saw.

Chainsaw Jim

Con Artist LLC

- Local time

- 6:08 AM

- User ID

- 836

- Joined

- Feb 8, 2016

- Messages

- 4,014

- Reaction score

- 96

- Location

- Springfield Oregon

Dammit Doc!...the monkey's legs are skinny enough without you taking food off his table. Lol

Joking aside, Doc is pretty much correct on what he said. I think a majority of the most important information on the subject requires advanced experience to understand.

If a person is not somewhat artistic with strong hands then it might not be their thing. In my opinion it requires above average carving type skills when it comes to actual grinding.

Joking aside, Doc is pretty much correct on what he said. I think a majority of the most important information on the subject requires advanced experience to understand.

If a person is not somewhat artistic with strong hands then it might not be their thing. In my opinion it requires above average carving type skills when it comes to actual grinding.

- Local time

- 9:08 AM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,614

- Reaction score

- 63,341

- Location

- Strong Island NY

If a used piston lines up with the saw piston I try to use it. That way the real piston doesn't get scratched up.

Different pistons can have different skirt and crown height. Even different skirt widths so u gotta be careful.

An 046 Meteor piston has .100 wider skirts on each side and a higher crown than oem. If you port it to the limits with a meteor, you'll have looser squish and skirt Freeport with an oem slug.

Different pistons can have different skirt and crown height. Even different skirt widths so u gotta be careful.

An 046 Meteor piston has .100 wider skirts on each side and a higher crown than oem. If you port it to the limits with a meteor, you'll have looser squish and skirt Freeport with an oem slug.

Al Smith

Here For The Long Haul!

- Local time

- 9:08 AM

- User ID

- 537

- Joined

- Jan 14, 2016

- Messages

- 6,636

- Reaction score

- 14,779

- Location

- North western Ohio

Well you hit the nail on the head with that one .It's just an engine. Invented long before any of us were born by dudes using slide rules. Casting their own cases and pistons. There have been books written about them long ago. Nothing new is happening. There are no secrets, just understanding.

.

I've seen a bunch of them .Some done by so called experts and many who are just interested people and most of the time there isn't that much difference in how they run .On forums you get a lot of bravado and BS,ego trips .Sparing roosters so to speak .Conversely many are down to earth people who would give you the shirt off their back if it were cold out ,my kind of people .

Years ago on a forum I'll never associate with again a simple question soon became a pissing match promoted by the site owner .It was fun for a while but soon became a pain in the arse to deal with .It was not educational by any means more recreational than anything .You have to sort it out .

- Local time

- 9:08 AM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,614

- Reaction score

- 63,341

- Location

- Strong Island NY

Next up is exhaust height. What it is stock matters. How much you drop the jug matters.

I didn't mention one important point about the base and band.

You need to mark the piston bottom at TDC at the bottom of the exhaust floor. That's the limit you can take off the base before it Freeports the piston skirt.

I didn't mention one important point about the base and band.

You need to mark the piston bottom at TDC at the bottom of the exhaust floor. That's the limit you can take off the base before it Freeports the piston skirt.

- Local time

- 9:08 AM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,614

- Reaction score

- 63,341

- Location

- Strong Island NY

I have no pic of this, sorry.

- Local time

- 9:08 AM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,614

- Reaction score

- 63,341

- Location

- Strong Island NY

If you do some measuring and all is right, you will find some saws will run well with a small band and base cut alone.

The exhaust roof and intake floor will move the least in degrees when a jug is dropped. The transfers will move more.

On a Stihl MS440, 10 out of the band and a base cut to get .020 squish and no port work will run right on the tail of a fully ported saw. That's with a timing advance and muff mod.

I'm sure that depends on the jug though. They have too little blowdown stock.

Also the lower the exhaust roof, the lower blowdown can be.

I'm doing my best to keep this straight, but it all works together. The best way to do this is to get a cheap jug and start grinding.

Everything works together and even when you think you've got it all understood, someone who is a beginner does it "all wrong" and builds a better/faster saw than you can.

The exhaust roof and intake floor will move the least in degrees when a jug is dropped. The transfers will move more.

On a Stihl MS440, 10 out of the band and a base cut to get .020 squish and no port work will run right on the tail of a fully ported saw. That's with a timing advance and muff mod.

I'm sure that depends on the jug though. They have too little blowdown stock.

Also the lower the exhaust roof, the lower blowdown can be.

I'm doing my best to keep this straight, but it all works together. The best way to do this is to get a cheap jug and start grinding.

Everything works together and even when you think you've got it all understood, someone who is a beginner does it "all wrong" and builds a better/faster saw than you can.

- Local time

- 9:08 AM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,614

- Reaction score

- 63,341

- Location

- Strong Island NY

Mount your timing wheel next. Use a piston stop to find TDC. You've found it when the wheel rotated in either direction stops at the exact same degree.

Mount your wheel with a guesstimate of BDC with the piston at it, but the wheel with BDC marking at the top.

Then move your wire for final adjustment.

Mount your wheel with a guesstimate of BDC with the piston at it, but the wheel with BDC marking at the top.

Then move your wire for final adjustment.

- Local time

- 9:08 AM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,614

- Reaction score

- 63,341

- Location

- Strong Island NY

Mark the exhaust port at tdc on you piston.

Take piston out and mark your bore with the skirts after you line up the mark you made in the exhaust port.

I leave 1/16" on both sides. I like worksaws, so there is more to be gained, but I don't care. Plus, if you pass your lines a bit, you're still ok.

You also have to measure overall width you marked. 65% of bore for a worksaw is safe.

I've yet to meet a Stihl with a skirt over 70%. But I've not touched every model,

Take piston out and mark your bore with the skirts after you line up the mark you made in the exhaust port.

I leave 1/16" on both sides. I like worksaws, so there is more to be gained, but I don't care. Plus, if you pass your lines a bit, you're still ok.

You also have to measure overall width you marked. 65% of bore for a worksaw is safe.

I've yet to meet a Stihl with a skirt over 70%. But I've not touched every model,

- Local time

- 9:08 AM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,614

- Reaction score

- 63,341

- Location

- Strong Island NY

Similar threads

- Sticky

- Replies

- 771

- Views

- 177K