chipper1

Here For The Long Haul!

- Local time

- 6:39 AM

- User ID

- 1463

- Joined

- Jun 25, 2016

- Messages

- 6,391

- Reaction score

- 24,031

- Location

- Grand Rapids Mi

Wow, you have an awesome wifeThe sign is 2 sided. Had thought about taking the other side out. It's a present from my wife so leaving alone for now. Glycol in floor. Propane boiler. Boiler and and plumbing was about 3k. IBC is the boiler, like it so far. Tubing and insulation in floor was left over from another job. Be about $500 in tubing and $1200 in foam.

I figure if I can find one for around 300-350 with two faces I can sell one face and then cut the frame in half build a back plate and use LEDs to light them. If not I could just buy the extrusion from a local sign supply house for the husky sign, but then I wouldn't get a stihl sign. I'd probably be alright without it though lol.

That's not bad at all. BIL had 3 k into his tubing insulation and the manifold, the footprint isn't as big as I want to build either$$$$.

Is glycol what everyone uses for a closed loop, I know nothing about them.

Wonder what it will cost a yr to heat the place.

Do you do that type of work then?

Thanks for the info.

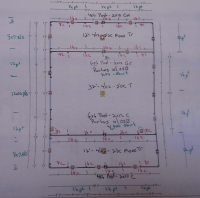

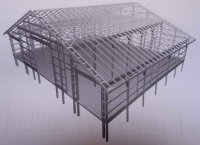

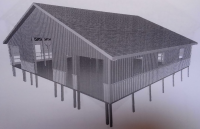

Here's the basics for mine. There will be no man door on the end, and the main 12 up door will be about 4' from the wall the man door in the print/rendering is near, I want enough room for shelving down that side and no outside access from a man door for security.