Wood Doctor

Edwin

- Local time

- 2:03 AM

- User ID

- 846

- Joined

- Feb 9, 2016

- Messages

- 2,513

- Reaction score

- 8,774

- Location

- Omaha, Nebraska

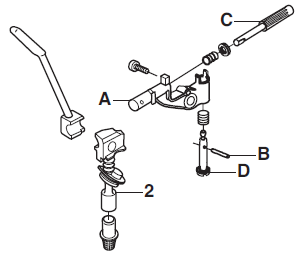

This oil leak is rather odd. My friend's Husqvarna 455 Rancher has hardly been used and the engine has really good compression and runs fine. It's been resting in a garage with a slow oil leak that I estimate at one drip every hour, so figure about a half ounce or so a day.. The cap is fine and the case is OK, so I conclude that it has to be in the pump assembly. I ordered a new one because it's an inexpensive set of parts. Here's the Service manual illustration:

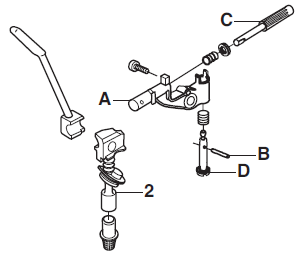

Here's a Pic with the side cover removed:

Overnight with the side cover in place, the saw leaked perhaps a quarter of an ounce. For the past seven hours with the side cover removed as shown in the pic, the leak has been zero. Gasp! That means to me that the pump assembly may be OK. If so, what is causing the slow leak with everything assembled? I'm stumped. Any suggestions?

TIA.

Here's a Pic with the side cover removed:

Overnight with the side cover in place, the saw leaked perhaps a quarter of an ounce. For the past seven hours with the side cover removed as shown in the pic, the leak has been zero. Gasp! That means to me that the pump assembly may be OK. If so, what is causing the slow leak with everything assembled? I'm stumped. Any suggestions?

TIA.