Everything has to match the saw, and different porting can change things.

I believe some 044/046 hybrids benefit by increasing case volume because the displacement is larger than the original 044.

If the saw sucks in more air / fuel due to the increase, transfer speed will not fall off so much.

Enlarging the case volume (usually by increasing the size of the lower transfers) will often increase low end torque and reduce peak RPM resulting in a saw with a broader power curve.

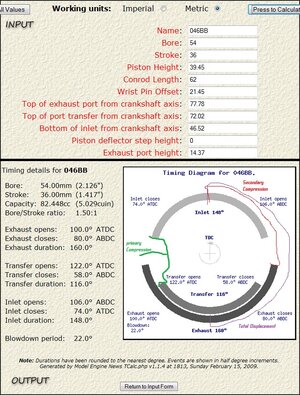

Of course, so much depends on other factors, but everything has to work together. Port timing, muffler modes, timing advance will all factor in.

IMO, results will always be somewhat based on experimentation, and if you find "lightning in a bottle", remember it!