Redbull661

661 hoarder (BlueBallz)

Last edited:

View attachment 90034

View attachment 90035

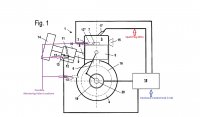

complete m-tronic system, can someone please show me all of the sensors

View attachment 90034

View attachment 90035

complete m-tronic system, can someone please show me all of the sensors

Just a couple amateurish questions that might help understand how m-tronic is working.

Would retarding the timing at WOT increase tolerance for an otherwise too lean condition at maximum RPM?

Is it possible that maximum RPM is not too lean for a computer that can react in a split second, and we don't tune to maximum RPM so that the motor doesn't suddenly become too lean if something changes?

Does the carb divider have a shape or inclination, such like an aircraft wing, that would induce lower pressure on one side?

I am still waiting for this.how it works in easy to understand words

Uh oh, dissent among the dividers.

Hope this isn't the start of the next popup wars...

After 13 pages how is the biggest mystery the internal workings of mtronic and no one has asked how come Mike - after years of telling us that the lightest saw you'd ever need is a 10mm 044 (or maybe a 362) - has bought a 261.

No worries Bill.

I think we are all way past having a "war" over how we build a saw.

Many ways to skin a cat.....and they all end up with a skinned cat.

I never judge, I just enable.

No worries Bill.

I think we are all way past having a "war" over how we build a saw.

Many ways to skin a cat.....and they all end up with a skinned cat.

I never judge, I just enable.

After 13 pages how is the biggest mystery the internal workings of mtronic and no one has asked how come Mike - after years of telling us that the lightest saw you'd ever need is a 10mm 044 (or maybe a 362) - has bought a 261.

And that is @blsnelling fault for sureI've been using a popup in a couple models too....

Hahaha

And that is @blsnelling fault for sure

BastardThat damn Brad.....