- Local time

- 10:36 PM

- User ID

- 25442

- Joined

- Nov 16, 2022

- Messages

- 274

- Reaction score

- 1,017

- Location

- Long Beach, IN

Many have questions on "plastics" used in chainsaws and repair techniques. I wanted to start this thread to share my knowledge and help others here who have helped me. Most of my professional career has been application development of plastics in new applications, much of it with nylon. I'm one of they guys who convinced the US automakers to switch from aluminum to nylon for intake manifolds in the early 90's. Great fun, I spent several days per week for years at Ford Engine Engineering.

There are many types of plastics. For the most part, chainsaws use nylon for covers, shrouds, etc. Technically called polyamide, abreviated to PA. It is the least expensive option for parts that require heat, oil, and fluid resistance. It's the material used these days for injection molded automotive valve covers, intake manifolds, radiators, timing gears/guides, etc. Chainsaw covers and parts have similar requirements. It's the same material used in nylon apparel, which is why it is so easy to dye black.

To increase performance, it is often reinforced with glass fibers or minerals. Think of how straw makes a brick stronger. Designed and molded properly, it's an excellent material. Here's a mineral filled nylon carburetor that my 1976 Lawn Boy was built with. I still use it all the time to cut my grass, I've never touched the carb except for the tuning screw.

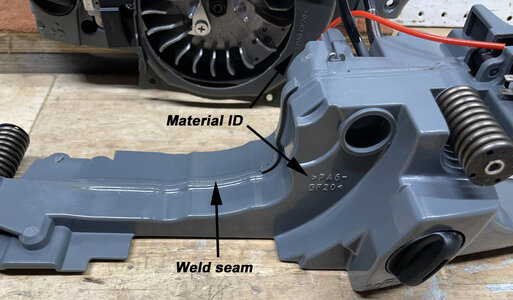

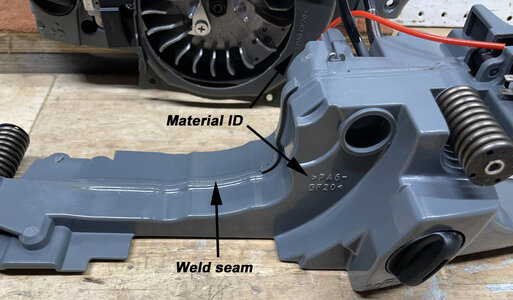

Here's the tank/handle from a G372XP I'm porting, note how it's marked :

Let's start with the weld seam, this one appears to be hot plate welded, like this:

Note material ID, this is found on a lot of parts made after the mid-90's, adopting the nomenclature used in the automotive world. Here's another example on the top cover for a G372XP:

Here's what that material ID means, PA6GF20

- PA = Polyamide, or nylon

- 6 means nylon 6, which is the most common type of nylon. Another type often used, especially in the automotive world, is 66, a different type of nylon with higher heat capability

- GF means glass filled, <1/8" length glass fibers compounded into the nylon. Think of fiberglass insulation strands, but real short.

- 20 means 20%, or 20% of the weight of the part is glass fiber. This is used to stiffen and reinforce the molded part

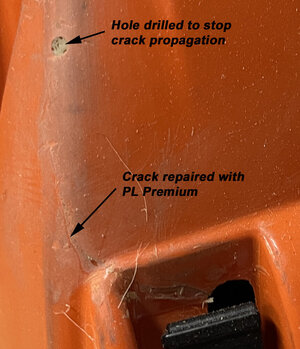

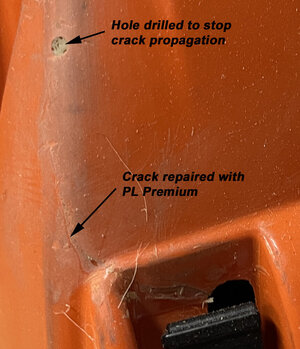

OK, so how can we fix one of these that breaks? Here's an example of PL Premium used to fix a cracked cover on my SIL's MS 251:

For nylons, PL Premium is an outstanding choice of adhesive. It's a moisture cured urethane that expands slightly when curing, filling any voids in the joint. It also is impervious to oils/solvents after 24 hours of exposure to humidity in the air. It's the same basic material used for truck bed liners, very tough stuff.

There are many types of plastics. For the most part, chainsaws use nylon for covers, shrouds, etc. Technically called polyamide, abreviated to PA. It is the least expensive option for parts that require heat, oil, and fluid resistance. It's the material used these days for injection molded automotive valve covers, intake manifolds, radiators, timing gears/guides, etc. Chainsaw covers and parts have similar requirements. It's the same material used in nylon apparel, which is why it is so easy to dye black.

To increase performance, it is often reinforced with glass fibers or minerals. Think of how straw makes a brick stronger. Designed and molded properly, it's an excellent material. Here's a mineral filled nylon carburetor that my 1976 Lawn Boy was built with. I still use it all the time to cut my grass, I've never touched the carb except for the tuning screw.

Here's the tank/handle from a G372XP I'm porting, note how it's marked :

Let's start with the weld seam, this one appears to be hot plate welded, like this:

Note material ID, this is found on a lot of parts made after the mid-90's, adopting the nomenclature used in the automotive world. Here's another example on the top cover for a G372XP:

Here's what that material ID means, PA6GF20

- PA = Polyamide, or nylon

- 6 means nylon 6, which is the most common type of nylon. Another type often used, especially in the automotive world, is 66, a different type of nylon with higher heat capability

- GF means glass filled, <1/8" length glass fibers compounded into the nylon. Think of fiberglass insulation strands, but real short.

- 20 means 20%, or 20% of the weight of the part is glass fiber. This is used to stiffen and reinforce the molded part

OK, so how can we fix one of these that breaks? Here's an example of PL Premium used to fix a cracked cover on my SIL's MS 251:

For nylons, PL Premium is an outstanding choice of adhesive. It's a moisture cured urethane that expands slightly when curing, filling any voids in the joint. It also is impervious to oils/solvents after 24 hours of exposure to humidity in the air. It's the same basic material used for truck bed liners, very tough stuff.

Last edited: