thompsoncustom

Super OPE Member

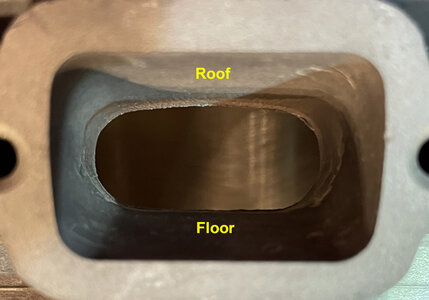

I was wondering what the limits were on how flat you could make the intake and exhaust roofs?

I know the worry is snagging a ring but couldn't you get around that by really beveling the roof? and with the roof really beveled would there really be an increase in ring wear?

just wondering what you guys thought and/or found out regarding port flatness.

I know there is a big difference in stock saws from pictures I've seen with some being almost flat and other being very curved.

I know the worry is snagging a ring but couldn't you get around that by really beveling the roof? and with the roof really beveled would there really be an increase in ring wear?

just wondering what you guys thought and/or found out regarding port flatness.

I know there is a big difference in stock saws from pictures I've seen with some being almost flat and other being very curved.