Philbert

Chainsaw Enthusiast

- Local time

- 6:08 PM

- User ID

- 737

- Joined

- Jan 30, 2016

- Messages

- 5,049

- Reaction score

- 21,628

- Location

- East Dakota

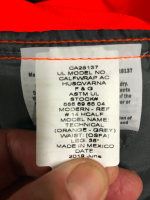

My Husqvarna chaps (several years old) were made in Mexico.

Philbert

Philbert

Interesting: the 'A' 'B', and 'C' levels of coverage described are different than those described for the European standard, in another article I read.Longest article I've seen on chainsaw chaps and pants.

There was a 'translate this page' option at the top when I opened it. Thanks!Several models, all in French.

This is the place to explore this type of nerdy stuff! I have learned a lot in the last few days! Thanks!I feel like I opened Pandora's Box here. But it is certainly shining a light on just how many people are making chaps, how many methods, formulas, combinations of materials are out there . . . . Essentially that is why I started this thread; to see how far we had progressed in the years since I last bought chaps

My Husqvarna chaps (several years old) were made in Mexico.

Philbert

This is the place to explore this type of nerdy stuff! I have learned a lot in the last few days! Thanks!

Philbert

As have I

I am almost ready for the pop quiz on Friday...

At the end of the day, good is meeting the applicable UL standard, it would be uncommon for them to be much above that regardless of price. A very very cheap pair of chaps that genuinely meets the UK standard will stop the saw the same as a very expensive pair that meets the same size but that is about where the comparison stops, much like a Ferrari will get you from a to b same as a beat up pickup truck. The extra you pay for in this case is branding and comfort. The difference in comfort between cheap and expensive is much more significant than you may believe...I feel like I opened Pandora's Box here

But it is certainly shining a light on just how many people are making chaps, how many methods, formulas, combinations of materials are out there

Essentially that is why I started this thread; to see how far we had progressed in the years since I last bought chaps

I wasn't looking for the cheapest but I also believe now that you can get a GOOD set without breaking the bank

I am not saying the BEST set because apparently that title is up for grabs, but a good pair at a decent price

Again, just looking for options

I am just as sure that if you cheap out you are essentially going to end up with weedeater chaps and when you need them you are going to regret it

As always, YMMV

Peace

Race saws built for competition in cants can hit speeds of 15-18k pretty easily out of the wood without a lot of loss in the cutsCheap chain is BS and has no place in my tool box, period.

@Definitive Dave

I'm sure your three cube is faster but...

What is the chain speed of your five cube saw on change-overs free revving over the cant?

At the end of the day, good is meeting the applicable UL standard, it would be uncommon for them to be much above that regardless of price. A very very cheap pair of chaps that genuinely meets the UK standard will stop the saw the same as a very expensive pair that meets the same size but that is about where the comparison stops, much like a Ferrari will get you from a to b same as a beat up pickup truck. The extra you pay for in this case is branding and comfort. The difference in comfort between cheap and expensive is much more significant than you may believe...

3/8” chain on a 11 pitch sprocket turning 18,000 rpm works out to 12,375 fpm chain speed. So faster than I was thinking but at this speed might need more than chaps to stop the possibility of a crank failure

Played with this in an A.S. post several years back:formula for chain speed in fpm

I didn't check your calculations, but if you are running an 11 tooth sprocket, and turning 18K RPM, you kinda' have to assume that you will be living over the edge, so to speak! Might want pants AND chaps, or one of those EOD suits from The Hurt Locker!3/8” chain on a 11 pitch sprocket turning 18,000 rpm works out to 12,375 fpm chain speed.

You posted that while I was posting that!Better wear cut pants with chaps over them

17 pin on a saw must require a custom bar, I know when I was helping my uncle figure out a wood processor he was building for someone we needed to take a harvester bar and cut the end off,then re machine the bar slot and oiler holes. None of the bars we could buy off the shelf were tall enough to accept the drive sprocket he needed with his motor/pump combo for the surface speed he wanted. Originally we were going to gear the drive up between the motor and sprocket to achieve the rpm we wanted but he wanted direct off motor so we had to make a custom bar. The sprocket was so large the chain came at the bar from a reverse angle. Sprocket was like 5/8” bigger in diameter than the bar was tall at mount. So custom bar with custom chains is what he got.