- Local time

- 11:11 PM

- User ID

- 26178

- Joined

- Feb 23, 2023

- Messages

- 1,746

- Reaction score

- 5,555

- Location

- Montana

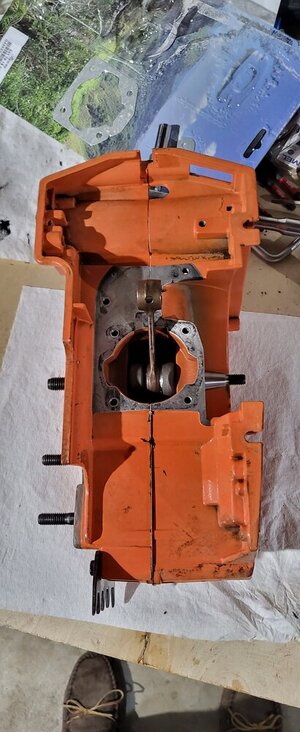

Alrighty now. Time to get some stuff put back together. Cleaning is behind and the smell of burning paint is before me. Later on yall will understand (might already) why I said that.

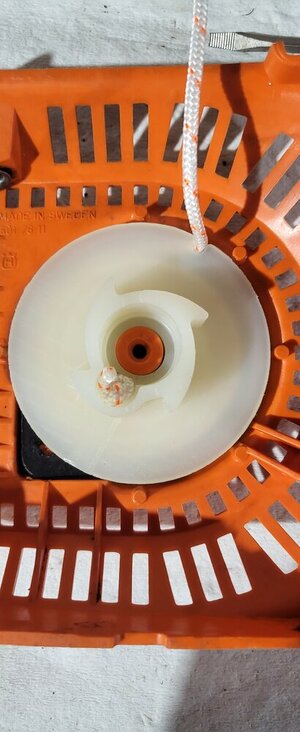

It's bearing time!! If you put the picture upside-down you can see the "made in Swedan" on the bottom. One bearing in.

I used a heat gun to install the bearings just like for taking them out. It was easier to install, than take them out. I also set the bearings in the freezer for a bit.

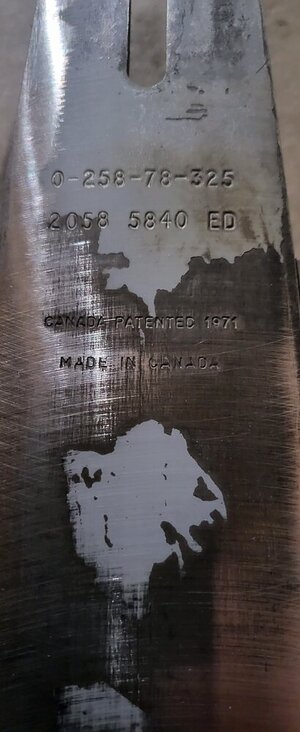

Last bearing in. I was going to take a close up shot of the bearing so yall could see the "Made in Germany" stamp.

A glamor shot of the crank for our members from Swedan!!

It's bearing time!! If you put the picture upside-down you can see the "made in Swedan" on the bottom. One bearing in.

I used a heat gun to install the bearings just like for taking them out. It was easier to install, than take them out. I also set the bearings in the freezer for a bit.

Last bearing in. I was going to take a close up shot of the bearing so yall could see the "Made in Germany" stamp.

A glamor shot of the crank for our members from Swedan!!