Had time to read the other thread. Good one there, too.

It's pretty well known that stock squish on these is in the .060 range..., but they still pull in the neighborhood of 160psi give or take due to a very compact combustion chamber. Even so, I still check squish when using any aftermarket top end that isn't a Meteor just to be safe. Dirko is my sealant of choice and I've never had a problem with it.

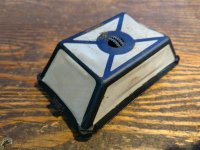

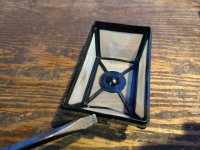

And here's is quick vac/pressure test approach using Gorilla Tape for checking the seals and intake bulkhead before putting everything back together. Works great on clean surfaces. Do vac first to seal it a little better than just pressing it on. Then it'll hold 6~7 lbs. of pressure no problem (if the surfaces were clean when the tape went on). Obviously a redneck leak check, but it's fast and if everything is tight you're good to go. If there's a leak you can trouble shoot it up to a point using pressure and soapy water before needing to go with block-offs for smaller leaks needing more pressure to isolate.

Anyway, I've taken some raggin' for the Gorilla Tape, but it works. Will get ya another 100 miles out of a pair o' cheap Nikes too!