farminkarman

I like the red & black ones

- Local time

- 8:18 PM

- User ID

- 13535

- Joined

- Aug 17, 2020

- Messages

- 4,997

- Reaction score

- 28,810

- Location

- Neenah Wisconsin

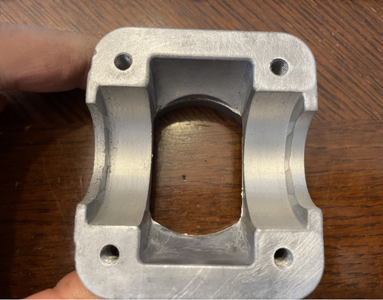

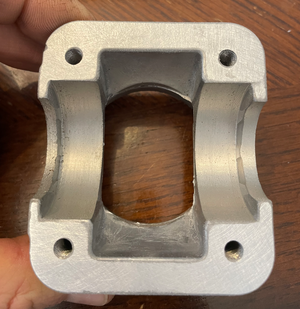

Alright gang, sounds like there is enough interest in a thread on building husky 350's and their related plastic-cased variants (Husky 340, 345 and Jred 2150...probably missing one). All of the saws in this family, including the 351, 346 oe & ne, 353; Jred 2149, 2152, and 2153 run the same stroke. The 340 and 345 utilize a 42mm clamshell style cylinder from the factory and the 350 and 2150 utilize a magnesium cylinder "riser" that allow the use of a removeable cylinder like pro-saws use. The earlier 350's came with an open-port 44mm cylinder, and the later 350's came with a 45mm cylinder with removable transfer port caps. The later 350's were known to vibrate the mufflers off and burn holes in the top of the oil tank. In my opinion, the coolest part of these cheaper saws is that you can turn them into a respectable firewood saw with basic mods. And if you want to do a high performance build with a 346xp top end, you can do that too. Later I will update this post with some important part numbers to reference for working on these saws. This thread will probably be somewhat slow to build as I don't have a lot of devoted shop time, be patient.

Relevant part number list:

537251302 - OEM partition and metal clamp upgrade kit

588775502 - 385/390xp Intake clamp

544809801 - 346xp muffler brace

PC2205 - Meteor brand flat-top piston kit

544142908 - OEM 346xp piston & cylinder kit

Relevant part number list:

537251302 - OEM partition and metal clamp upgrade kit

588775502 - 385/390xp Intake clamp

544809801 - 346xp muffler brace

PC2205 - Meteor brand flat-top piston kit

544142908 - OEM 346xp piston & cylinder kit

Last edited: