Paul Lloyd-Jones

Just learning

- Local time

- 6:46 PM

- User ID

- 27214

- Joined

- Aug 1, 2023

- Messages

- 39

- Reaction score

- 55

- Location

- Inverness, FL, USA

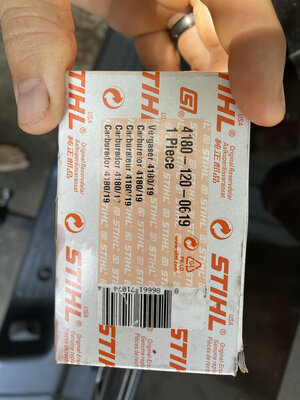

I just put a new OEM carb on a Stihl HT131 polesaw. Can someone tell me how to adjust it or direct me to a thorough reference? The saw manual info is extremely brief. I have extensive experience with these saws, but very limited experience with carb tuning.

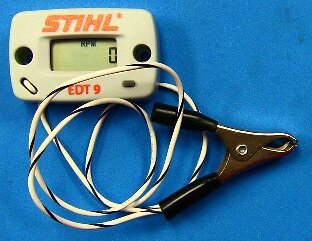

Probably unnecessary ramblings, but this was how it went for me: When I first tried starting it, it fired immediately, but didn't stay running. I messed with the low end for several minutes and the idle a bit and couldn't get anything but a sputter, and only if I kept the throttle all the way open. I was about to give up, but then I tried messing with the high a bit and got it running and idling well. It actually sounded pretty normal, but I held a tach to it and found that it was only getting up to 9000 rpms. I thought it was supposed to be closer to 12,000 (I'm seeing now that it's supposed to be 10,200) then messed with the high end screw a bit. I am confused at how much I was able to turn the screw with very little effect. I'm talking about like 8 full turns (I'm not sure I actually counted). Is that normal? Do these not come with limiters? The low turned a whole bunch too, but at least it seemed to actually be doing something. After I tried getting the high end up, I started adjusting everything again, and I just made it wonky. Finally gave up on it, figuring I'd be able to find a video or manual reference that would give me a whole tuning procedure or at least initial adjustment settings, but I spent a while looking and found nothing. I need help.

Probably unnecessary ramblings, but this was how it went for me: When I first tried starting it, it fired immediately, but didn't stay running. I messed with the low end for several minutes and the idle a bit and couldn't get anything but a sputter, and only if I kept the throttle all the way open. I was about to give up, but then I tried messing with the high a bit and got it running and idling well. It actually sounded pretty normal, but I held a tach to it and found that it was only getting up to 9000 rpms. I thought it was supposed to be closer to 12,000 (I'm seeing now that it's supposed to be 10,200) then messed with the high end screw a bit. I am confused at how much I was able to turn the screw with very little effect. I'm talking about like 8 full turns (I'm not sure I actually counted). Is that normal? Do these not come with limiters? The low turned a whole bunch too, but at least it seemed to actually be doing something. After I tried getting the high end up, I started adjusting everything again, and I just made it wonky. Finally gave up on it, figuring I'd be able to find a video or manual reference that would give me a whole tuning procedure or at least initial adjustment settings, but I spent a while looking and found nothing. I need help.