- Local time

- 6:41 AM

- User ID

- 10894

- Joined

- Nov 6, 2019

- Messages

- 335

- Reaction score

- 996

- Location

- Salem, Missouri

I've always hand sharpened everything. Didn't much case for the concept of the grinder.

I've got a friend closing down a small engine. He called me today and told me to come out and he'd give me some saw equipment for free.

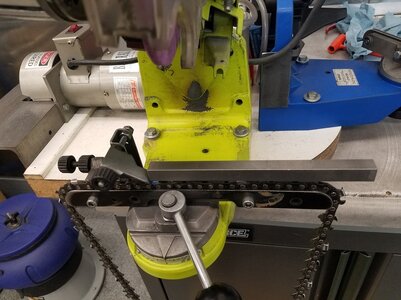

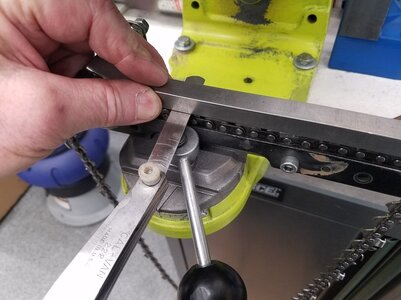

He gave me a pair of grinders. One of them says it's an efco I believe and the other looks identical just a different color.

Are these grinders going to produce a sharp chain if setup correctly or are they known to have issues??

Sorry but I know absolutely nothing about grinding chain.

I've got a friend closing down a small engine. He called me today and told me to come out and he'd give me some saw equipment for free.

He gave me a pair of grinders. One of them says it's an efco I believe and the other looks identical just a different color.

Are these grinders going to produce a sharp chain if setup correctly or are they known to have issues??

Sorry but I know absolutely nothing about grinding chain.