S&S_Work_Saws

Well-Known OPE Member

- Local time

- 7:26 AM

- User ID

- 10894

- Joined

- Nov 6, 2019

- Messages

- 94

- Reaction score

- 220

- Location

- Salem, Missouri

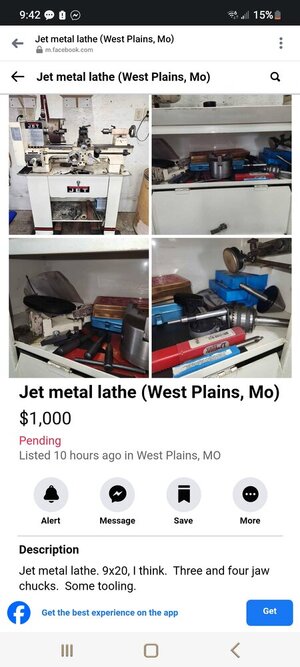

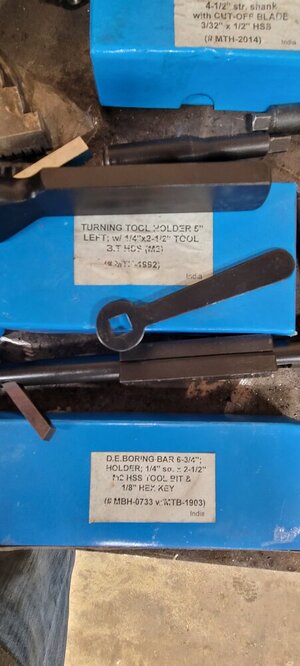

I'm scheduled to go pickup a used lathe tomorrow. It includes a whole bunch of tools and a 4 jaw independent chuck. It also has the matching stand its made to sit on. The price is great and it's only a couple hours away.

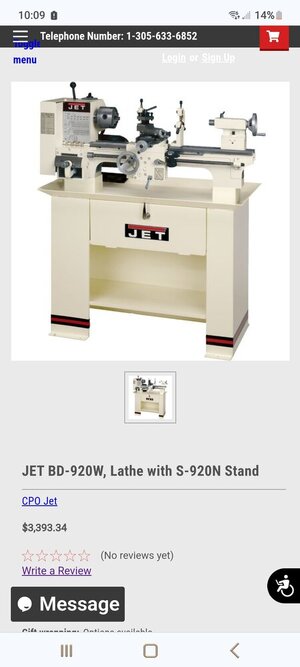

It's a Jet 9x20. Has anyone ever owned one of these machines or been around one?? I've not been around a lot of Jet brand equipment. I'm sure it's probably made in China or Taiwan like so many others.

This will be my second lathe and I learned ALOT from the first little setup I had. If I had more space I'd go bigger but I'm very limited on space. Cylinders are the biggest thing I'll be using it for and I think a 9" swing should cut about amy squish band, right??

It's a Jet 9x20. Has anyone ever owned one of these machines or been around one?? I've not been around a lot of Jet brand equipment. I'm sure it's probably made in China or Taiwan like so many others.

This will be my second lathe and I learned ALOT from the first little setup I had. If I had more space I'd go bigger but I'm very limited on space. Cylinders are the biggest thing I'll be using it for and I think a 9" swing should cut about amy squish band, right??