- Local time

- 5:38 PM

- User ID

- 5156

- Joined

- Jan 24, 2018

- Messages

- 9,681

- Reaction score

- 38,435

- Location

- Extreme Southeast CA

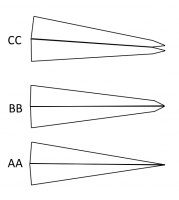

Maybe screw some hard heads together with the screws at an angle with the tips sticking out the opposite side to prevent popping out