czar800

Mastermind Approved!

- Local time

- 11:54 AM

- User ID

- 533

- Joined

- Jan 14, 2016

- Messages

- 7,167

- Reaction score

- 37,484

- Location

- Ellwood City

I was disappointed by the Diamond Brand CBN wheels that I received, but recognize that they might not have been representative of all.

Frustrating part of it was their sales office is 20 miles from my house, and I asked, several times, if I could stop in to discuss my concerns. They declined, and told me that I just needed to practice using a chain grinder.

Philbert

Yeah, I tried to intentionally 'burn' (overheat) a cutter, juts because the reviews said that they were less likely to do this. I was able to do this, although, again, it was intentional. But I could not grind much faster that with a well dressed AO wheel. There was definitely less dust produced that with my AO ('pink', green, whatever color vitrified) wheels. I was just not happy with the coarse grind; it might be acceptable to others. I might have been happy with a finer grit, but they blew me off as someone inexperienced with a grinder.Tried their wheels twice burned cutters on the first wheel, contacted customer service, was told that the grit sometimes isn't exposed enough through the binder material and they would send a replacement.. Replacement did the same thing..returned and moved on.

Yeah, I tried to intentionally 'burn' (overheat) a cutter, juts because the reviews said that they were less likely to do this. I was able to do this, although, again, it was intentional. But I could not grind much faster that with a well dressed AO wheel. There was definitely less dust produced that with my AO ('pink', green, whatever color vitrified) wheels. I was just not happy with the coarse grind; it might be acceptable to others. I might have been happy with a finer grit, but they blew me off as someone inexperienced with a grinder.

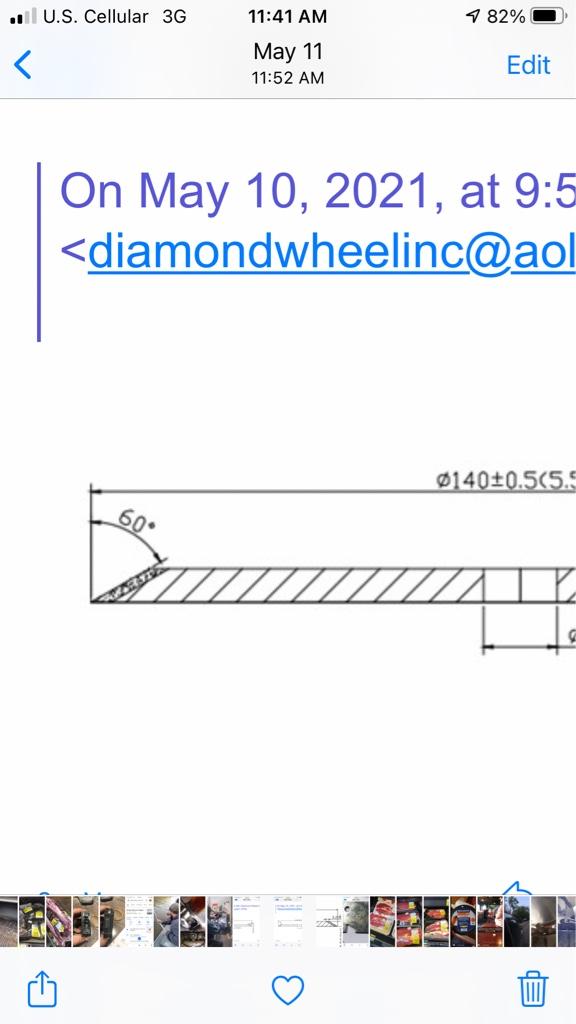

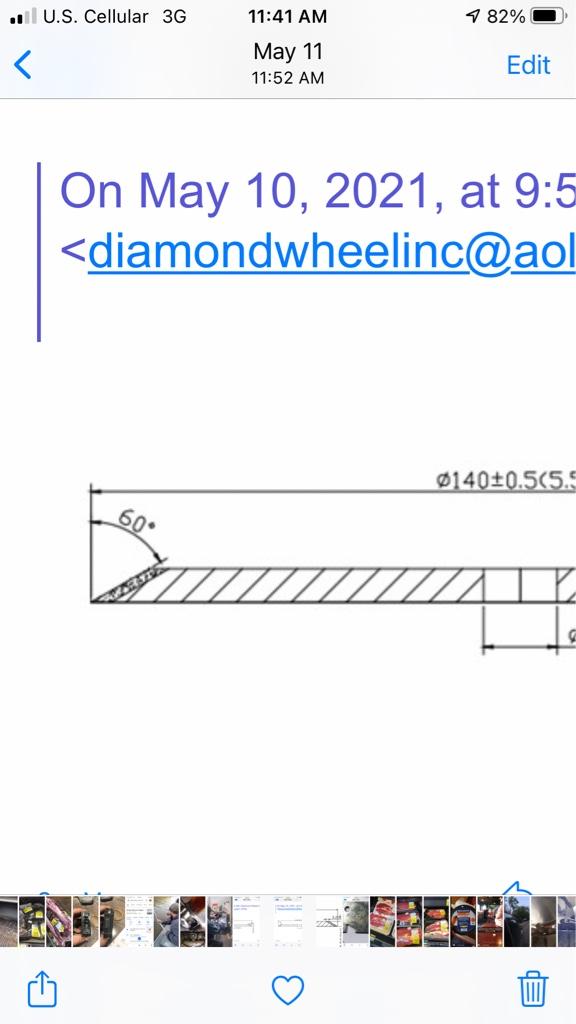

View attachment 326027

Philbert

@super3 had it done several years ago. Might be able to shed some light

did you get that from L&M sharpening? I have one identical

Awesome. Thank you Brad!

Sent from my iPhone using Tapatalk

Do it through email and they will send you the the draft drawing for you to okay before putting into production

Sent from my iPhone using Tapatalk

Seems like he had a raker wheel made. Not a square grind wheel.I just tapped his pm box out of curiosity, just wondering about how the performance was without being able to chase the angles as the tooth wears back..forward lean in particular, I like a bit of self feeding and wouldn't you have to get a few CBN wheels in different profiles to address this? As the tooth wears back maybe change to a different wheel to keep up? Might be a option, but you'd need a few wheels to keep each style of tooth the same throughout its life, then what for the other profiles you like, another batch in different profiles? I think I'd need a numbering system to keep it all square..lol

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Has anyone looked into having a custom diamond wheel made for square grinding? I know it’s been asked before at times and the answer always is that nothing is currently built but I think it would be worth the price for a custom wheel to never have to dress it.

Sent from my iPhone using Tapatalk

Seems like he had a raker wheel made. Not a square grind wheel.

Maintaining the corner would be my only concern. Even with cbn, I could see the corner potentially rounding off over time

Correct

Same thoughts I had and what grit also.

I like 60 for round but don't think that is going to be a good choice for a nice corner.

I called Diamond for a price to plate the blank I made.

They wanted 250+

Radiac done it for 80

Man, I'm in the same boat! I have spent a year with my super jolly and am ready to go the next level. Don't get me wrong, this grinder has paid for itself 3 times over in the past year and i do like it, but the "slop" since day one has just been bugging me. One option is for me to make all new bushings, bearing inserts, etc and really turn this into an industrial unit, but at some point that project will turn into a point of diminishing returns. Absolutely LOVE the hydraulic clamping feature, HUGE time saver. Would not even CONSIDER going back without one.

Looks like it has been mentioned in an earlier post, foot pedal for the USG - I think I'll have to look into that.

As far as CBN wheels, wow, I've simply EXCELLENT results. I'm using Foley Belsaw brand wheels.

Stick with Foley I didn't have to try at all with the Diamond wheel brand.. bluing and burr came standard.I’ve only used the foley belsaw brand wheels and they work way better for me than the pink wheels. They’re fast and you’d have to try to get the cutter hot. I’m afraid if I’d get a wheel made by diamondwheelinc.com it wouldn’t work as good as the foley belsaw wheels.

Sent from my iPhone using Tapatalk

Dan , I'll bring a Diamond cbn wheel up to your place and we can compare it to the foley belsaw wheels .I’ve only used the foley belsaw brand wheels and they work way better for me than the pink wheels. They’re fast and you’d have to try to get the cutter hot. I’m afraid if I’d get a wheel made by diamondwheelinc.com it wouldn’t work as good as the foley belsaw wheels.

Sent from my iPhone using Tapatalk

Where do you get the Foley wheels at? I’ve only used Diamond and ones from Ahlborn. I’ve like both, don’t burn the cutter, never have to dress them or reshape.I’ve only used the foley belsaw brand wheels and they work way better for me than the pink wheels. They’re fast and you’d have to try to get the cutter hot. I’m afraid if I’d get a wheel made by diamondwheelinc.com it wouldn’t work as good as the foley belsaw wheels.

Sent from my iPhone using Tapatalk