My english is not the best but...

i was allways planing to do it first, and then talk about it. And im not very kind of sharing this kind of info...

So, after a year of tinkering, experimenting, mine is working for a 10 months now, more than 20 fuel-tanks trough (started as Jonsered 2171 and it is in Husky color's now)...

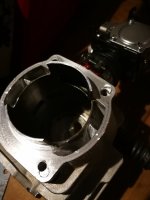

im using a E*HO 900EVL piston and Husqvarna 385xp Cylinder. Piston-ring pins are slightly better spaced then the ST*HL's option. Not the best alignment still - ring-pins very close to the upper transfers edges... but, as there is no replacement for displacement, .... and i was stubborn to finish this project... and now after this build, i can say, it can be done.

U need to do spacer's inside the EC*O piston/on the crankshafts rod.

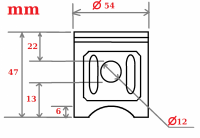

Lathe work, height of the piston... cut the roof and base. my piston is roughly 47mm tall...

Lathe work on the cylinders bottom, cut the skirt to 57mm...

Mill thinner the top cooling-fin (half as thin as it was), and re-shape it, so the modded top cover will fit,

Plug the cylinder mounting bolt holes, drill new ones. (i made a plywood templates for this in cnc-mill)

Slight dremel clearence work in the cranckcase for pistons movement,

top cover cutting, cut some inner walls away, and customise the filter cover so the spark plug stays hidden.

im using also cutted Walbro RWJ-4b (massaged throttle plate, no mid splitter, planing to try a 395XP carburettor),385/390xp intakeboot, 372xp x-torq filter mount, unlimited coil, and upper port "massaged" muffler.

and the abomination works....