Rich Fife

Sally slap my ass

- Local time

- 8:10 AM

- User ID

- 26245

- Joined

- Mar 4, 2023

- Messages

- 839

- Reaction score

- 1,483

- Location

- Central New York

Well, this is a little different build than all of my previous builds... I have a bunch of parts kicking around, some parts I forgot about.

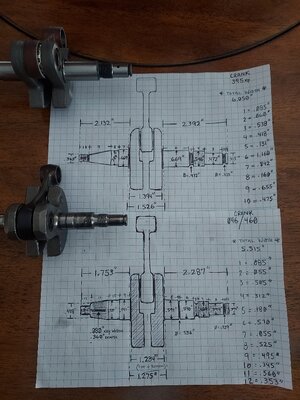

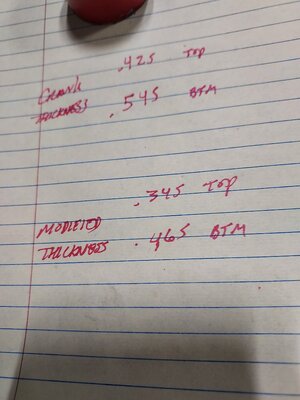

I'm starting with an 046 case, a 395xp crank, a 660 big bore cylinder and either a 395 or a 661 piston... I won't know the exact route until I get the case together. Below are some of the parts as well as the progress thus far.

I'm starting with an 046 case, a 395xp crank, a 660 big bore cylinder and either a 395 or a 661 piston... I won't know the exact route until I get the case together. Below are some of the parts as well as the progress thus far.