MattG

Chainosaurus Rex

- Local time

- 11:53 AM

- User ID

- 3111

- Joined

- Apr 30, 2017

- Messages

- 896

- Reaction score

- 1,432

- Location

- Cambridgeshire, England

Morning Folks,

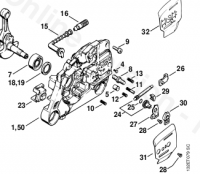

I've been slowly dismantling a complete(ish) but non runner 044. I've got all sorts of ideas for it project wise (e.g. I have a 12mm wrist pin crank to swap in, then perhaps convert to 460 hybrid). However as I strip it I'm obviously uncovering what's wrong with it etc. Well the piston is well toasted and has start of a hole forming on it's crown. So I wanted to know why, the carb settings (1 turn out on both) seemed fine, so I go leak hunting in my usual way, off with the f/w and the clutch, and block off the exhaust and inlet. Needless to say the mityvac won't hold any +ve pressure whatsoever. I can already hear the leak, and it's on the PTO side:

Above is a shot after I'd started to investigate matters. I'm not sure whether you should +ve pressure test a 044 in this state, since I'm now curious as to whether the clutch back washer is needed to press that bush further into the engine. However, that's how I usually test, since it gives you good visibility of the problems.

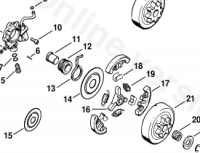

Anyway I could see/hear the air leaking from here, especially between the bush and the shaft itself. However after removal of the bush it looks as if the crank seal itself aint in great shape either.

So now I'm curious how does the whole thing work? Is the bush supposed to spin with the crank, i.e. rotate against the seal? The wear pattern on the bush suggests this to be more likely:

than it staying fixed against the seal inner lips and the crank spinning within it.

So can someone please explain this to me, i.e. what edge(s) must be sealed, what spins during operation and what shouldn't, etc. etc. ?

I've been slowly dismantling a complete(ish) but non runner 044. I've got all sorts of ideas for it project wise (e.g. I have a 12mm wrist pin crank to swap in, then perhaps convert to 460 hybrid). However as I strip it I'm obviously uncovering what's wrong with it etc. Well the piston is well toasted and has start of a hole forming on it's crown. So I wanted to know why, the carb settings (1 turn out on both) seemed fine, so I go leak hunting in my usual way, off with the f/w and the clutch, and block off the exhaust and inlet. Needless to say the mityvac won't hold any +ve pressure whatsoever. I can already hear the leak, and it's on the PTO side:

Above is a shot after I'd started to investigate matters. I'm not sure whether you should +ve pressure test a 044 in this state, since I'm now curious as to whether the clutch back washer is needed to press that bush further into the engine. However, that's how I usually test, since it gives you good visibility of the problems.

Anyway I could see/hear the air leaking from here, especially between the bush and the shaft itself. However after removal of the bush it looks as if the crank seal itself aint in great shape either.

So now I'm curious how does the whole thing work? Is the bush supposed to spin with the crank, i.e. rotate against the seal? The wear pattern on the bush suggests this to be more likely:

than it staying fixed against the seal inner lips and the crank spinning within it.

So can someone please explain this to me, i.e. what edge(s) must be sealed, what spins during operation and what shouldn't, etc. etc. ?