Jake Dykstra

Super OPE Member

- Local time

- 6:36 AM

- User ID

- 7947

- Joined

- Nov 25, 2018

- Messages

- 250

- Reaction score

- 700

- Location

- NW Washington

Disregard^^^ I didn't see the beginning of thread at first

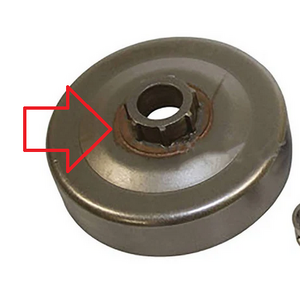

How did you accomplish this, did you desolder the center of the clutch cover and swap (small style/large style)? I am looking for a way to get a .404 rim (large style) on a small style clutch cover. Basically I want to run a .404 chain on a MS 261...just for the fun of it.Only thinks I did different was I made a 8t .325 sprocket for the large style clutch rim because the 9t in hard wood dulls easy

I hadn't thought about modifying the sprocket. Unfortunately I don't have access to a lathe. I was was looking at the clutch drum and replacing the small center post with the larger one to accommodate a .404 post. Not sure if the solder can be heated up and this one removed and the larger format version added. I misunderstood what you had did, had I looked at the first page of the post I would have seen. Makes sense now.The outer sprocket would need cut out in the middle and the smaller diameter turned down to press and weld. Assuming the difference in size was enough to not interfere with the tooth spline grooves.