Don't thank me, it was 166 that clued us in.

Now then pretty sure the spring fixed em, on the ported one, I am convinced it did fix it. This issue is weird, as I said in my earlier posts, the issue for me is when they set for a few days.

Once started and ran they are fine, and start continuously the rest of the day with no problem. Go to fire it up the next day, and they start the first pull. Let them set 4 or 5 days and that's when their flooded? Weird huhh?

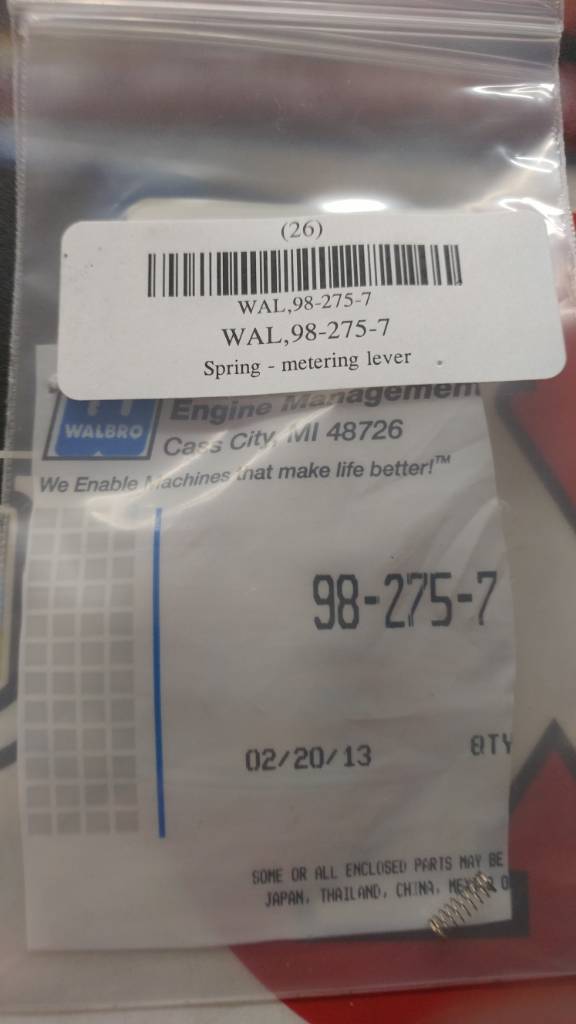

So after replacing the springs, the ported one starts just fine one pull on choke after setting for a few days, only adjustment I had to make was setting the idle screw, nothing else.

Now on the stock one the problem still exists, it is flooded on 2 attempts after setting 4 days each time, I did adjusts the idle screw and the low jet screw on this one, I am now thinking that maybe it is a problem with the vent? Both times after the 4 day experiment I took the carbs off and gas just squirts out of the fuel line, so there's gotta be a pressure problem? So one is resolved and the other I will keep fiddling with! Anybody else have a problem getting these throttle cable sleeves line back in the housing correctly?