paragonbuilder

Mastermind Approved!

- Local time

- 4:34 PM

- User ID

- 384

- Joined

- Jan 2, 2016

- Messages

- 9,229

- Reaction score

- 33,865

- Location

- Norwich, CT

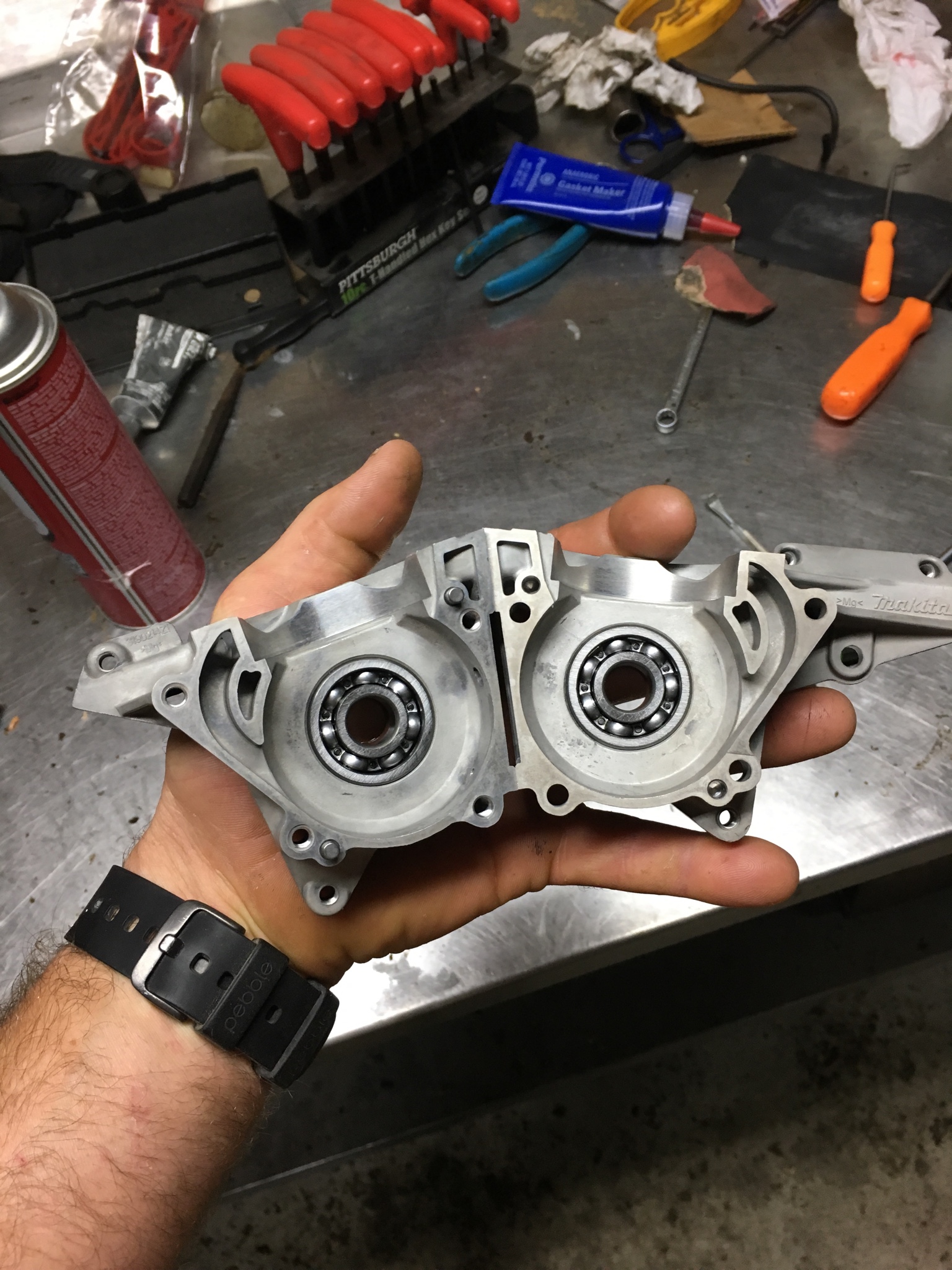

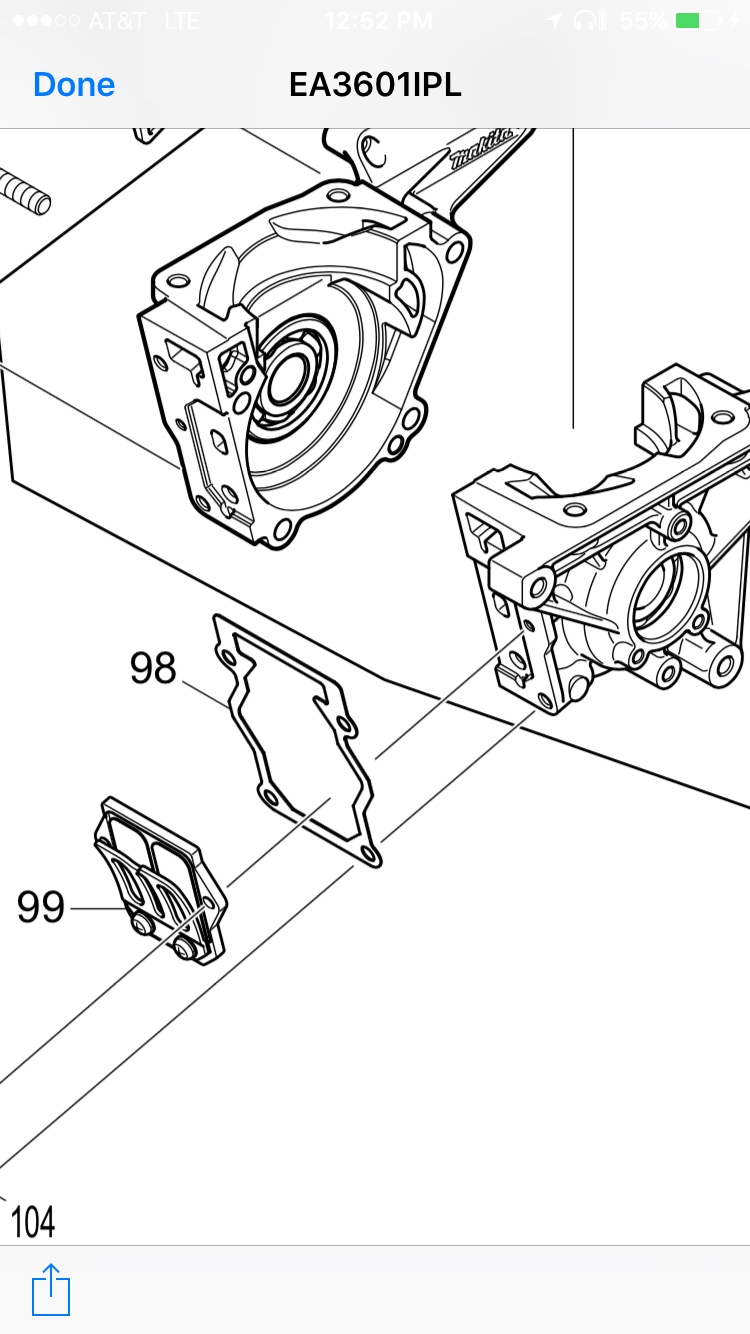

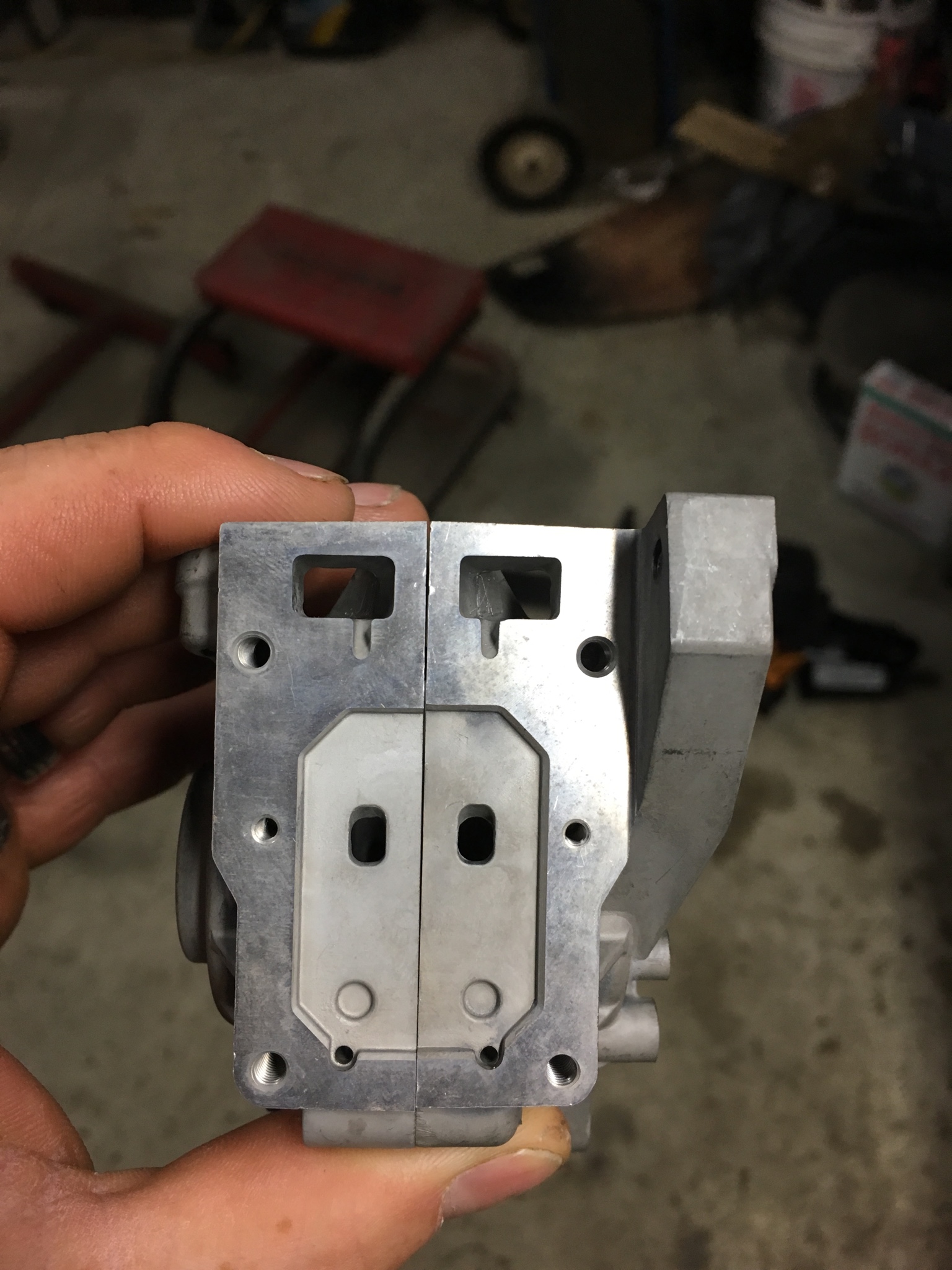

Piston is smooth sided, no strato ports in it. All that happens down below.

And the machining on this cylinder and the transfer port angles are truly the best I have ever seen.

I'll get more pics this weekend and we can start discussing it

Sent from my iPhone using Tapatalk

And the machining on this cylinder and the transfer port angles are truly the best I have ever seen.

I'll get more pics this weekend and we can start discussing it

Sent from my iPhone using Tapatalk