- Local time

- 9:11 PM

- User ID

- 522

- Joined

- Jan 12, 2016

- Messages

- 3,946

- Reaction score

- 26,019

- Location

- Iowa City

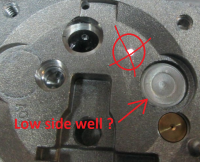

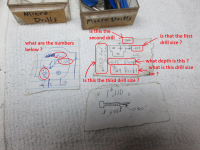

How modified must a saw be before you start drilling the idle feed hole and can you show how you plug the feed passage from the main nozzle when you do?

Also, do you change or make the main jet smaller? The only modified 3120 carb I've had my hands on was almost too rich with the stock jet so you'd have to have the added adjustment at 1/16 turn or less.

Also, do you change or make the main jet smaller? The only modified 3120 carb I've had my hands on was almost too rich with the stock jet so you'd have to have the added adjustment at 1/16 turn or less.