- Local time

- 2:24 AM

- User ID

- 5156

- Joined

- Jan 24, 2018

- Messages

- 7,947

- Reaction score

- 29,399

- Location

- Extreme Southeast CA

I’d probably rip it apart and hack a regular control setup onto it. But I run a machine and welding shop…

I havent yet. I have a feeling he will just say "order a new cylinder/pump" which will cost me $350, plus his time, thats probably $550 and ive already dropped over $200 at that rate I might as well just buy a new one and try to sell this one off for as much as I can get to someone that can fix it themselves.Have you talked to the hyd shop?

Is that the control valve or the pressure relief valve? it looks like the pressure relief to me. I don’t think your pressure relief is sticking open or leaking.Thanks for all the replies.

I attached pictures of the control valve. it looked pretty clean inside, im not sure how it would be leaking unless its just poor design?

according to the manual its the control valve, it sits behind the handle.Is that the control valve or the pressure relief valve? it looks like the pressure relief to me. I don’t think your pressure relief is sticking open or leaking.

he didnt mention anything about it, just that the seal in the cylinder was damaged.I’m thinking it is the advance / retract valve, which could be as simple as a standard ball valve with a cross drilled ball in a seat. If that seat is worn or the valve body is cracked, then it can bypass when under a load. That’s where I would focus my attention. if it is part of the cylinder as you state, then it should have been checked and o-rings/seals replaced during the service. Be worth asking,if the service was recent

nothing gets hot to the touch, and the fluid isnt hot either.

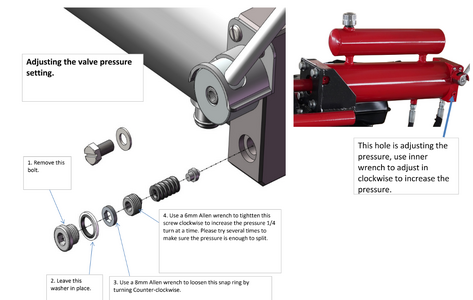

Turn it in another 1/4 turn for more power, but don’t overdo it. When something has to give, best it’s the relief valve.