forgero

OPE Member

- Local time

- 5:28 AM

- User ID

- 28022

- Joined

- Dec 3, 2023

- Messages

- 11

- Reaction score

- 11

- Location

- Seattle, WA

I have had a Performance Built 13-ton log splitter I bought at Lowes for about 5 years now which has overall been pretty good for a small operation. Details on it can be seen here: https://www.cnsuperpower.com/produc...lt-13ton-gasoline-log-splitter-half-beam.html.

I had two problems initially. First, the rod took about 5 seconds to get up to full speed. Second, it did not have splitting power after a few minutes of use.

Things I tried: I replaced the hydraulic fluid and cleaned out the filter, which had rubber bits clogging it. I replaced the cap to the hydraulic tank (the plastic cover was cracked). I also replaced the engine oil, however the engine seems to be operating fine.

These two things did not solve either issue so I took only the cylinder to a hydraulic shop mechanic who took it apart and replaced the seals. this solved the issue with the rod being slow which explains why the rubber bits were in the filter. however, it did not fix the issue with the splitting power lasting only a few minutes.

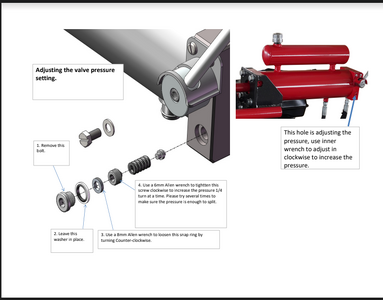

I contacted the manufacturer who suggested I change the pressure setting, which involved removing a cap on the control valve and turning a nut with an allen wrench. this did not solve the issue.

As the cap was new and I had read some things about a lack of airflow possibly being an issue I opened it up and found a spring with what looked like a sponge on the end. I removed this and replaced the cap, now it will run for about 15-20 minutes before it loses splitting power. this made me wonder if its an issue with air intake or overheating, but I know nothing about hydraulics and have no experience repairing equipment.

Before I spend several hundred more dollars on a repair shop, I am hoping the experts on this site will be able to help me figure out what the issue is so either I can fix it myself or decide if its time to hang it up.

I am just about at my wits end, so any help is very much appreciated.

I had two problems initially. First, the rod took about 5 seconds to get up to full speed. Second, it did not have splitting power after a few minutes of use.

Things I tried: I replaced the hydraulic fluid and cleaned out the filter, which had rubber bits clogging it. I replaced the cap to the hydraulic tank (the plastic cover was cracked). I also replaced the engine oil, however the engine seems to be operating fine.

These two things did not solve either issue so I took only the cylinder to a hydraulic shop mechanic who took it apart and replaced the seals. this solved the issue with the rod being slow which explains why the rubber bits were in the filter. however, it did not fix the issue with the splitting power lasting only a few minutes.

I contacted the manufacturer who suggested I change the pressure setting, which involved removing a cap on the control valve and turning a nut with an allen wrench. this did not solve the issue.

As the cap was new and I had read some things about a lack of airflow possibly being an issue I opened it up and found a spring with what looked like a sponge on the end. I removed this and replaced the cap, now it will run for about 15-20 minutes before it loses splitting power. this made me wonder if its an issue with air intake or overheating, but I know nothing about hydraulics and have no experience repairing equipment.

Before I spend several hundred more dollars on a repair shop, I am hoping the experts on this site will be able to help me figure out what the issue is so either I can fix it myself or decide if its time to hang it up.

I am just about at my wits end, so any help is very much appreciated.