Interesting.The 394 didn't use an exhaust gasket. If you want one, you have to purchase the gasket for the 395.

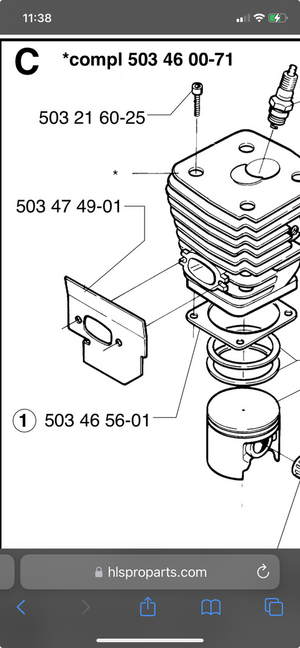

The heat shield acted as a gasket in the 394.

I will likely still add one. Still trying to picture a heat shield during my muffler removal and reinstall. It did not have one of those either.