- Local time

- 4:19 AM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,371

- Reaction score

- 61,582

- Location

- Strong Island NY

Rainy weekend on the way.

I am gonna need to drop the cylinder a bit more to cover the ring pin. The cylinder has that typical large bevel on the intake roof, so the pin seems more covered than it actually is.

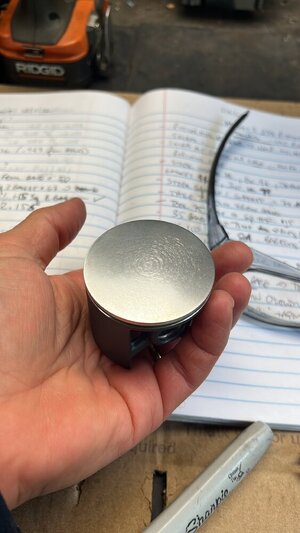

Bought some extra pistons for experimentation. What I noticed, on both the Hyway and the dukes, is that the pin bore isn’t centered in the boss. The meteor has a perfectly centered pin hole in the boss. Not sure if it matters or not, I’m sure they finish the hole to be perpendicular to the skirts at the time of final machining, but it kinda makes one question the overall QC on the slugs.

I am gonna need to drop the cylinder a bit more to cover the ring pin. The cylinder has that typical large bevel on the intake roof, so the pin seems more covered than it actually is.

Bought some extra pistons for experimentation. What I noticed, on both the Hyway and the dukes, is that the pin bore isn’t centered in the boss. The meteor has a perfectly centered pin hole in the boss. Not sure if it matters or not, I’m sure they finish the hole to be perpendicular to the skirts at the time of final machining, but it kinda makes one question the overall QC on the slugs.

Last edited: