MattG

Chainosaurus Rex

- Local time

- 10:08 PM

- User ID

- 3111

- Joined

- Apr 30, 2017

- Messages

- 896

- Reaction score

- 1,432

- Location

- Cambridgeshire, England

I got bored this morning and decided to investigate why the 036 I picked up this summer, whilst generally being nice and clean, was getting more oil on the floor than on the chain. Nothing could have prepared me for what would be revealed as I pulled things off....

Check out the groovy silvery glitter finish

So clearly the cuts in the pipe at the outlet is where it was taking a pi$$

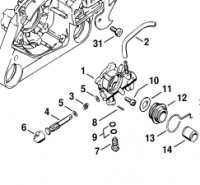

I was also wondering why the oilworm drive (see top right) seem to be separate as soon as I got the clutch off?

Not to be forgotten, a brand new clutch (though not OEM ) with very sexy mismatched springs:

) with very sexy mismatched springs:

Buying saws from ebay is such an adventure, on my side of the pond!!

Check out the groovy silvery glitter finish

So clearly the cuts in the pipe at the outlet is where it was taking a pi$$

I was also wondering why the oilworm drive (see top right) seem to be separate as soon as I got the clutch off?

Not to be forgotten, a brand new clutch (though not OEM

Buying saws from ebay is such an adventure, on my side of the pond!!