Matt I'm not sure, from what you said... And me how I wote it. If you or I got the right or wrong end of the stick, so to speak,

The engine pulses a pressure wave. This wave pumps/sucks fuel via the carb bit with those flappy oneway valves.

When there's enough positive pressure ( this bit looses me on some carbs) from fuel the meatering leaver opens and or the diaphragm pushes on the leaver allowing some fuel (more or less depending on pop off pressure) into the chamber. And or while the fuel is being used it draws a slight lower pressure to allow the diaphragm push the leaver.

In this chamber (not all carbs are the same, I think ?) this carb has a hole for the H jet and a L jet (the brass bit under the meatering leaver).

Let's start with the H hole as it's more simple.

Fuel gets sucked into this because of a venturi effect going through the mouth over the carb, the H needle screw is the bottle neck, thus opening the needle more fuel.

Now for the L jet. Umm...

So as before the engine is running and there is a Venturi, A lower pressure.

Because of the butterfly only being partly/slightly open this lower pressure is in a different place.

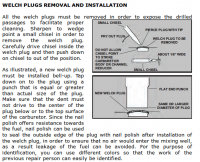

Somehow fuel is drawn into the Welch plug. But fuel has to come from the meatering leaver chamber and go through the Welch plug and pass by the L screw, (this carb as Terry said has a limiting jet. No matter how much you open the L screw the bottle neck becomes is this brass thing under the leaver)

Iirc, the reason there is the Welch plug, it's made to enable the manafacturing processes.

That made my brain work a bit to hard...

If I missed/skipped or got it wrong..... Feel free to correct my 2 cell size brain, I'm sure one cell was still half a sleep.

Edit: when I say Venturi, it is a reduced relative pressure