MattG

Chainosaurus Rex

- Local time

- 3:23 PM

- User ID

- 3111

- Joined

- Apr 30, 2017

- Messages

- 896

- Reaction score

- 1,432

- Location

- Cambridgeshire, England

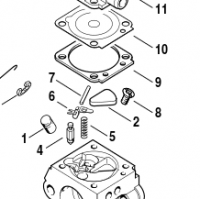

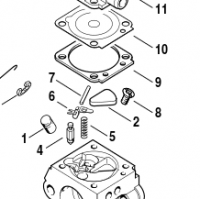

So when I first got mad on saws I got a broken 200T. I ended up changing out a heap of stuff just for the fun of it, seals, pipes, piston, rings etc. When I got it running, it seemed pretty strong, but it had a problem, with starting from cold, where straight after firing on full-throttle it would fuel starve. I'd already done a full carb service (diaphragms, needle etc.) so I took @Lone Wolf s advice, and did a "quick accelerator pump" block, i.e. I forced out the plug shown by the pencil here

and filled the space with JB weld.

I don't think it made much difference. That was nearly 3 years ago. I've since put on an old non-acc-pump carb on that saw, and it goes like greased lightning.

Anyway, the other day, I decided to dig the old carb out and have another go with it. I did the acc pump block "again", but I used the method outlined by this guy:

https://www.arboristsite.com/community/threads/200t-carburetor-accel-pump-block-off.238372/

basically, you take the acc pump piston out, toss away the spring and 0-ring, and jb weld it back, sealing all the edges of the piston in the bore to stop any leaks.

In addition to that I cleaned the carb (again!) stripped anything off it and soaked it in gas for 2 days.

After reassembly with this "supposedly mended" carb, I was able to choke the saw, but again (!!!) the saw would lean-fuel-starve on fast idle.

The saw was almost impossible to get it to pick up at all off idle. I tried with everything on the L screw from 3/4 to 3 whole turns out.

Eventually I got the saw idling (very fast) by turning the LA right in. However, it was almost impossible to dial in full revs, it just lean bogs horrendously. I could once nurse it to full throttle, but even then it has NO GUTS between that and 3k.

The carb seems good only for spares. Seeing as I have basically filled the acc pump circuit up with JB weld, I'm wondering what else could be wrong......

My gut feeling is that one of L speed holes is completely blocked and I can't clear it. What else can I try (before binning it)? What about pushing out the welch plug that is in the metering chamber?

i.e. the part marked 2 in the above picture. Should I remove that? Does that give better access to cleaning all the fuel channels??

Sorry about the big essay! Just wanted to get the whole problem down and explain what I've done already. Note IS A CARB PROBLEM - the saw runs like a banshee with a good carb

and filled the space with JB weld.

I don't think it made much difference. That was nearly 3 years ago. I've since put on an old non-acc-pump carb on that saw, and it goes like greased lightning.

Anyway, the other day, I decided to dig the old carb out and have another go with it. I did the acc pump block "again", but I used the method outlined by this guy:

https://www.arboristsite.com/community/threads/200t-carburetor-accel-pump-block-off.238372/

basically, you take the acc pump piston out, toss away the spring and 0-ring, and jb weld it back, sealing all the edges of the piston in the bore to stop any leaks.

In addition to that I cleaned the carb (again!) stripped anything off it and soaked it in gas for 2 days.

After reassembly with this "supposedly mended" carb, I was able to choke the saw, but again (!!!) the saw would lean-fuel-starve on fast idle.

The saw was almost impossible to get it to pick up at all off idle. I tried with everything on the L screw from 3/4 to 3 whole turns out.

Eventually I got the saw idling (very fast) by turning the LA right in. However, it was almost impossible to dial in full revs, it just lean bogs horrendously. I could once nurse it to full throttle, but even then it has NO GUTS between that and 3k.

The carb seems good only for spares. Seeing as I have basically filled the acc pump circuit up with JB weld, I'm wondering what else could be wrong......

My gut feeling is that one of L speed holes is completely blocked and I can't clear it. What else can I try (before binning it)? What about pushing out the welch plug that is in the metering chamber?

i.e. the part marked 2 in the above picture. Should I remove that? Does that give better access to cleaning all the fuel channels??

Sorry about the big essay! Just wanted to get the whole problem down and explain what I've done already. Note IS A CARB PROBLEM - the saw runs like a banshee with a good carb