Philbert

Chainsaw Enthusiast

- Local time

- 1:53 PM

- User ID

- 737

- Joined

- Jan 30, 2016

- Messages

- 5,049

- Reaction score

- 21,621

- Location

- East Dakota

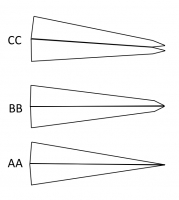

I have heard different definitions for 'single taper wedge' and 'double taper wedge', along with 'single lift' and 'double lift' felling wedges.

To add to the confusion, 'Double Taper' is the brand name for a line of plastic wedges, so ALL of their wedges are 'Double Taper wedges'!

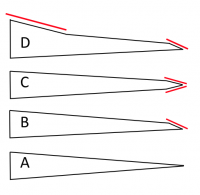

Which wedges in the illustration below do you call 'single taper' and which do you call 'double taper'? I am assuming that wedge 'D' would be a 'triple taper' or 'double lift' for felling?

Philbert

To add to the confusion, 'Double Taper' is the brand name for a line of plastic wedges, so ALL of their wedges are 'Double Taper wedges'!

Which wedges in the illustration below do you call 'single taper' and which do you call 'double taper'? I am assuming that wedge 'D' would be a 'triple taper' or 'double lift' for felling?

Philbert